Wall sandwich panels:

٭ Different types of wall sandwich panels offered by Apadana Borj Pooshesh Engineering Technical Group are as follows:

٭ Different types of wall sandwich panels offered by Apadana Borj Pooshesh Engineering Technical Group are as follows:

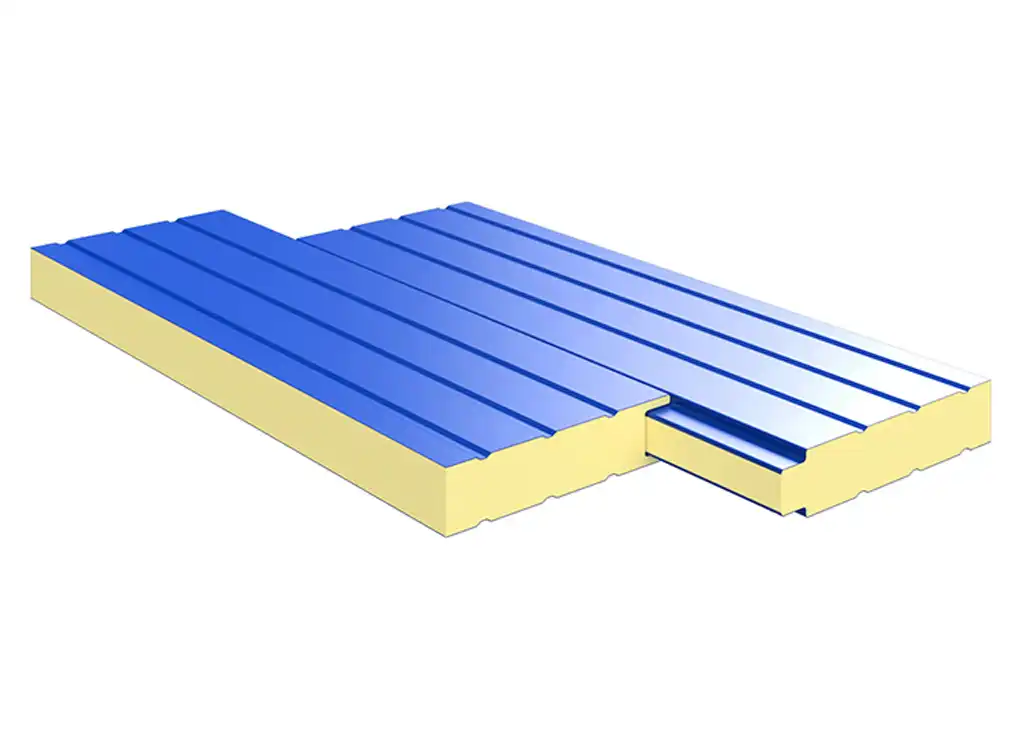

These sandwich panels are the preferable choices for both internal partition walls and external walls in metal structures. They are exceedingly popular with builders and designers. The grooves in traditional wall sandwich panels result from the superior adhesion of the foam to the sheet and the increased strength of the sheet. A dazzling array of colors, lengths, and thicknesses, ranging from 3 to 15 cm, are available in these fabulous sandwich panels.

| Technical Specifications | |

| Foam | PIR / PUR |

| Sheet material | Double-sided grooved/smooth sheet (galvanized/Aluzinc/aluminum) |

| Density | 40Kg/m3 |

| Thickness (cm) | 2-15 |

| Length (m) | 2-13/60 |

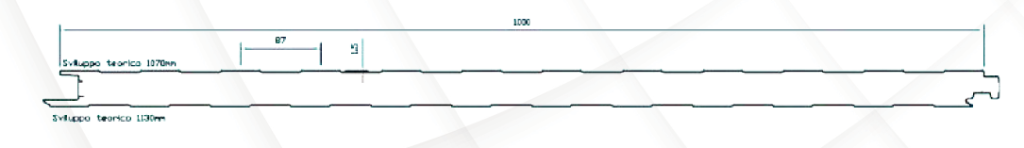

| Useful width (m) | 1 |

| Length (m) | Color scheme |

Some features of these sandwich panels are as follows:

The following table presents the technical specifications and load capacities of sandwich panels

| Insulation Layer Polyurethane | 30-40Kg/m3(Standard) Insulation Density | ||||||

| Sheet

Thickness |

Insulation Thickness | U values

(w/m2k) |

Support Span (cm) | ||||

| 100 | 120 | 160 | 200 | ||||

| Loud Spring (Kg/m2) | |||||||

| 0.48/0.48 | 40 | 0.55 | 626 | 509 | 365 | 239 | |

| 50 | 0.44 | 681 | 561 | 422 | 283 | ||

| 60 | 0.37 | 708 | 614 | 470 | 328 | ||

| 100 | 0.22 | 953 | 823 | 661 | 516 | ||

| w/mk 0.022 Heat Transmission Coefficient | |||||||

| 25 db Sound Insulation | |||||||

| (DIN 4102) B2+ Flammability | |||||||

Double-sided galvanized Aluzinc/aluminum wall sandwich panels:

Double-sided galvanized sandwich panels are among the products of Apadana Borj Pooshesh Engineering Technical Group, commonly utilized in the construction of walls for various structures such as industrial sheds, factories, shelters, and cold storage facilities. Here you can find valuable and useful information about this popular product.

The wall serves as a crucial element of a building, fulfilling various roles such as ensuring security, delineating internal spaces, and supporting the weight of the roof and other structural elements. In traditional construction techniques, these responsibilities were designated to a wall composed of a single material; however, in modern practices, each of these functions is performed by a distinct component. A notable advancement in wall construction is the production of double-sided galvanized sandwich panels. This product ensures the integrity of the structure while clearly defining the interior spaces. A sandwich panel typically features an insulating foam core that is sandwiched between two outer layers. These panels consist of materials that are both strong and lightweight while taking up minimal space.

Insulating foam:

In the extraordinary range of our products, we leverage the astounding capabilities of polyurethane to produce exceptional insulating foam. Polyurethane is the world’s most renowned foam, produced by combining polyol and isocyanate in a specially designed chamber. It is then meticulously cut to the exact dimensions required.

Steel sheet:

The polyurethane foam is encased in galvanized metal. Galvanized steel refers to a steel sheet coated with a layer of zinc metal that enhances its resistance to corrosion through the galvanizing process. This process not only creates a protective layer but also enhances the resistance of the parent metal. This metal sheet is typically utilized in its natural state, though it can be coated with a range of colors in a furnace.

Primer:

Primer bonds layers of a double-sided galvanized sandwich panel together through the perfect combination of pressure and heat. This primer has excellent adhesion and fills every seam and gap between the foam and sheet for a perfect finish.

Advantages of double-sided galvanized wall sandwich panels:

Strength and impenetrability:

External walls must be built not only to support their own weight but also to ensure protection against intruders. Walls covered with sandwich panels offer a robust and impenetrable solution, thanks to their construction with durable galvanized sheets and polyurethane insulating foam. Double-sided galvanized wall sandwich panels serve as an effective barrier against heat and sound transfer while also deterring the intrusion of animals and pests. Their antibacterial properties make them suitable for use in the construction of sanitary environments including cold stores, warehouses, and clean rooms.

Light weight:

The lower weight of components of a structure leads to an extended useful lifespan and enhances their resistance to damage from accidents, e.g., earthquakes. Known for their impressive strength, sandwich wall panels are also some of the lightest options available for the construction of walls. The lightweight design of these panels minimizes maintenance and transportation expenses while accelerating installation and execution processes.

Providing more space:

Expanding living quarters is a top priority for both architects and their clients. Compared to more traditional building materials, wall panels are substantially thinner. Therefore, these panels can be used on both interior and exterior walls to create a great deal of additional space.

Key considerations regarding the installation of double-sided galvanized wall

sandwich panels:

Price of double-sided galvanized Aluzinc/aluminum wall sandwich panels:

Apadana Borj Pooshesh Engineering Technical Group is dedicated to delivering high-quality products. Therefore, we offer double-sided galvanized Aluzinc/aluminum wall sandwich panels with a wide range of lengths, thicknesses, and colors at competitive prices. Please contact our sales team to place an order or inquire about the pricing of double-sided galvanized Aluzinc/aluminum wall sandwich panels.

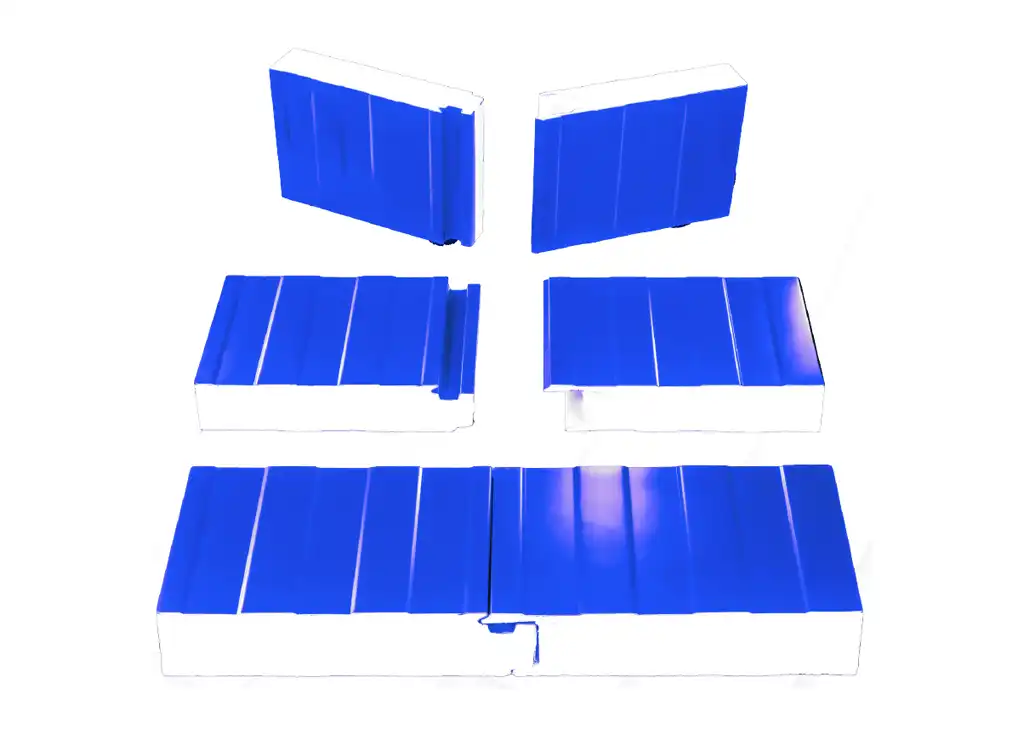

Another type of sandwich wall panels is the model with concealed screws. As the name implies, this product cleverly conceals the screw in the installation of the sandwich panel, ensuring that it remains out of sight thanks to its unique section in the wall façade. The concealed screw sandwich panel is crafted just like the classic sandwich wall panel, with the sole distinction being its cover section designed to elegantly conceal the screws and connections. This amazing sandwich panel comes in a variety of thicknesses ranging from 3 to 15 cm.

Concealed screw sandwich wall panels serve as a prefabricated solution for covering both the interior and exterior walls of buildings. The unique characteristic of these panels lies in their installation technique. This approach conceals the screws within the panel grooves, resulting in a completely uniform exterior appearance of the wall, free from visible bolts and nuts.

Different types of internal foam in concealed screw wall panels:

The internal foam of concealed screw wall panels serves as the essential core of this panel type, significantly contributing to thermal and acoustic insulation and moisture and fire resistance, along with influencing the weight and final cost of the panel. Selecting the appropriate type of foam relies on several considerations, e.g., the panel’s intended use, environmental factors, and the project’s budget.

The most common types of internal foam utilized in the production of concealed screw wall panels are as follows:

Polyurethane (PU):

Polystyrene (EPS):

Mineral wool:

Glass wool:

The primary advantage of the panels offered by Apadana Borj Pooshesh Engineering Technical Group, compared to the panels from other companies, is their superior durability, along with enhanced heat and cold insulation and improved thermal insulation. The optimal overlap (tightness) in the joint area is attained through the use of specialized sealing joints that incorporate minimal engineering allowances (regarding error margins) throughout the production process:

The following table briefly compares different types of foams.

| No | Type of foam | Advantages | Disadvantages | Common applications |

|

1 |

Disadvantages |

Very high thermal and acoustic insulation, high resistance, excellent adhesion |

Expensive |

Cold stores, clean rooms, pharmaceutical industries |

|

2 |

Polystyrene |

Reasonable price, good thermal insulation |

Less fire resistance, deformation at high temperatures | Commercial and residential buildings |

|

3 |

Mineral wool |

High fire resistance, good sound insulation |

Higher price, sensitivity to moisture | Industrial and public buildings |

|

4 |

Glass wool |

Good thermal and acoustic insulation, reasonable price |

Sensitivity to moisture, risk of skin and lung irritation | Residential and commercial buildings |

Types of exterior sheets of concealed screw wall sandwich panels:

The exterior sheet of concealed screw wall panels is usually made of galvanized, Aluzinc, or steel sheets.

Best types of foam for concealed screw wall sandwich panels:

Polyurethane is regarded as the optimal choice for the internal foam of concealed screw wall panels because of its exceptional characteristics, e.g., superior thermal and acoustic insulation, moisture and fire resistance, excellent adhesion to metal sheets, and an extended service life.

Advantages of concealed screw wall sandwich panels:

Technical specifications of concealed screw wall sandwich panels:

The technical specifications of a concealed screw wall panel might vary in its thickness, dimensions, external sheet, and foam type. However, these panels typically exhibit the following features:

Materials:

Thermal characteristics:

Acoustic specifications:

Mechanical specifications:

Chemical specifications:

Other specifications:

Importance of technical specifications:

Dimensions of concealed screw sandwich panels:

According to standards, these panels are usually 12 m in length and 1 m in width; however, these dimensions are flexible and can be changed as needed.

Installation of concealed screw wall sandwich panels:

The panels can be installed either horizontally or vertically with the use of specialized screws. The screws are positioned within the grooves integrated into the panels and are concealed with decorative covers following installation.

Key considerations regarding the installation of concealed screw wall panels:

Price of concealed screw wall sandwich panels:

Apadana Borj Pooshesh Engineering Technical Group is dedicated to delivering high-quality products. As such, we offer concealed screw wall sandwich panels in a range of lengths, thicknesses, and colors at competitive prices. Please contact our sales team to place an order or inquire about the pricing of concealed screw wall sandwich panels.

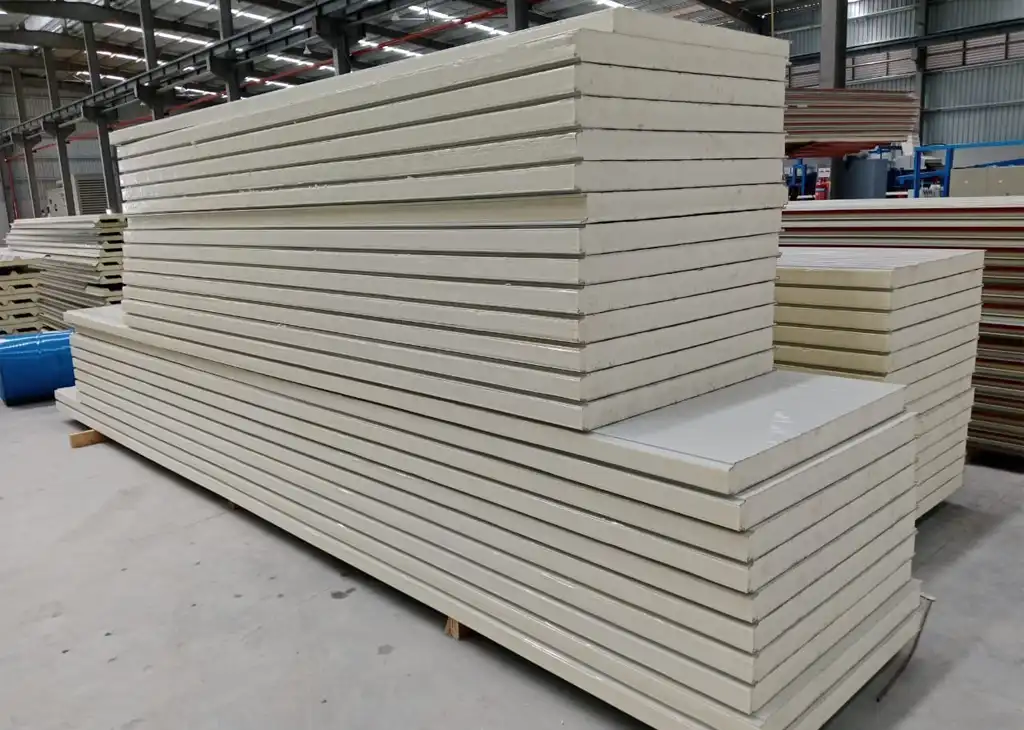

Sandwich panels of cold storage walls:

PUR/PIR cold storage sandwich panels are designed for warehouse structures that maintain internal temperatures as low as -25°C. Cold storage sandwich panels can be installed in both vertical and horizontal orientations. The panel edges are precisely cut, resulting in a very low linear thermal conductivity coefficient, while also ensuring complete sealing and vapor tightness.

Price of cold storage wall sandwich panels:

Apadana Borj Pooshesh Engineering Technical Group is dedicated to delivering high-quality products. Therefore, we offer cold storage wall sandwich panels with a wide range of lengths, thicknesses, and colors at competitive prices. Please contact our sales team to place an order or inquire about the pricing of cold storage wall sandwich panels.

Clean room wall sandwich panels with smooth sheets:

Clean room sandwich panels are utilized in environments where maintaining hygiene is crucial, and the use of sandwich panels with grooved sheets is not feasible. This type of sandwich panel is used in both the roof and the wall in such places. Clean rooms are environments designed to minimize the exchange of air, ensuring a controlled atmosphere free of substances like dust, airborne microbes, liquid vapors, and similar elements. A clean room serves as a regulated space that provides protection against various forms of contamination and microbes, ensuring the manufacturing of products or services that are sensitive to such factors. In these highly controlled environments, it is absolutely essential to keep all external airflow at bay. Anyone who wishes to enter or leave these spaces must first pass through a thorough air shower and put on the designated specialized attire to ensure the utmost safety and cleanliness. Therefore, it is essential to utilize specialized ceilings and walls to reduce the likelihood of air infiltration and exfiltration. Sandwich panels are used in the design and construction of clean rooms in structures that are highly sensitive. These sandwich panels typically feature a smooth finish on both sides, one smooth side, or one grooved side, effectively preventing dust and bacteria from accumulating. Another characteristic of these sandwich panels is their exceptional resistance to corrosion, decomposition, microorganisms, and bacteria.

Clean room sandwich panels are usually used for covering the walls and roofs in the following settings:

Apadana Borj Pooshesh Engineering Technical Group presents clean room sandwich panels featuring a flat sheet thickness of 0.6 mm, available in a variety of colors.

Price of clean room wall sandwich panels:

Apadana Borj Pooshesh Engineering Technical Group is dedicated to delivering premium products. Therefore, we offer clean room sandwich panels with a wide range of lengths, thicknesses, and colors at competitive prices. Please contact our sales team to place an order or inquire about the pricing of clean room sandwich panels.

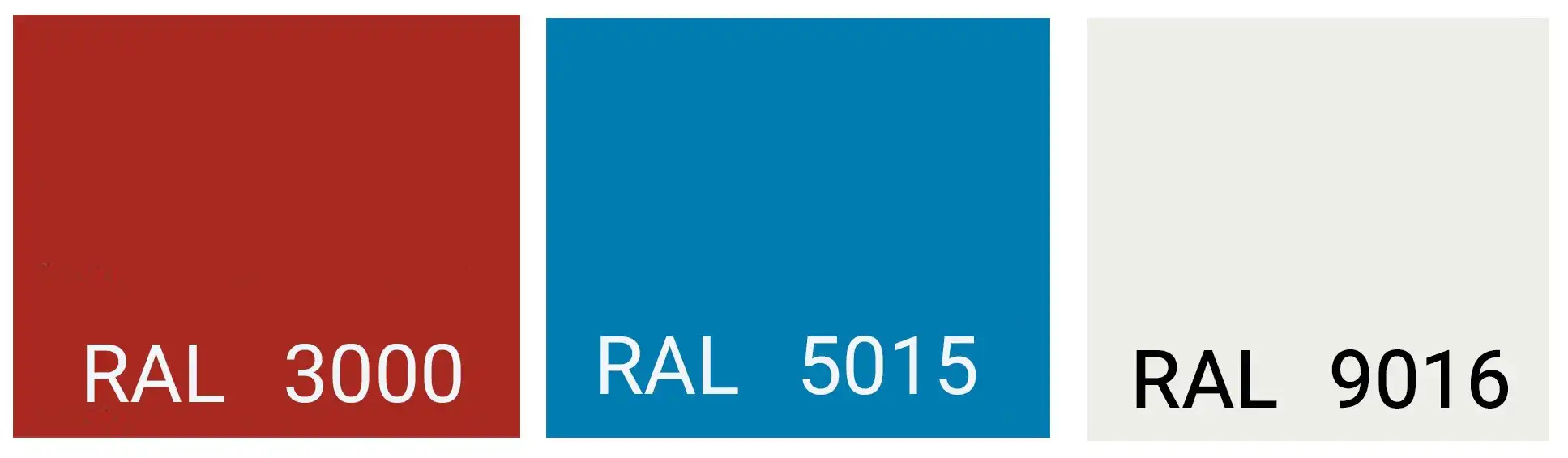

Different colors of wall sandwich panels:

Standard Colors

Special Colors