Steel deck:

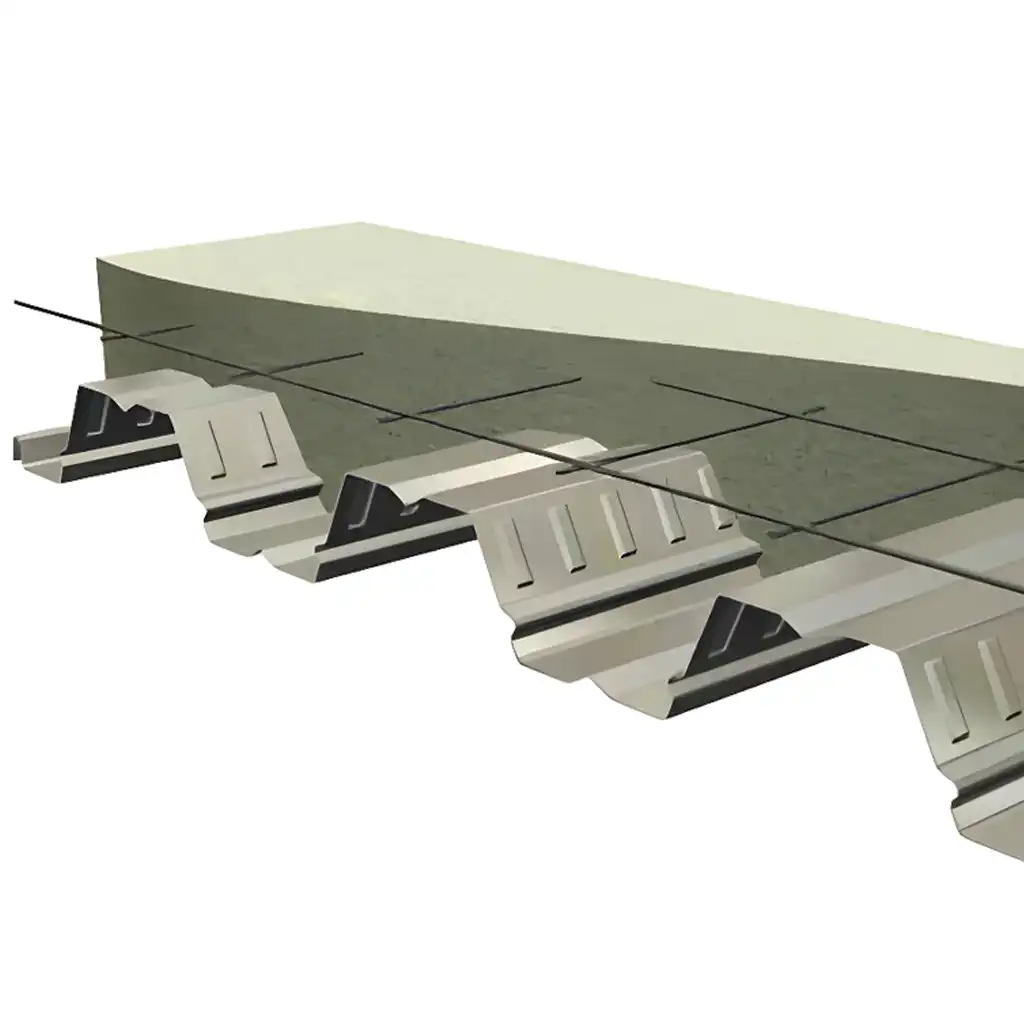

The roof is one of the most crucial elements of any building. This crucial component acts as a robust shield, safeguarding the structure from rain and snow, direct sunlight, strong winds, and more. However, it creates a sense of harmony and linkage between the dimensions of elements like walls and columns. Historically, roofs were constructed using substantial materials like bricks, cement, and concrete. Research, trials, and hands-on experiences have demonstrated that a building’s roof, when designed to be lightweight yet durable, contributes to an extended lifespan and enhanced resilience against occurrences like earthquakes. Several methods have been developed to reduce the weight of the roof, one of which is the use of steel decks. In this section, we will explore the various features of this method in greater detail. This type of roof consists of a blend of steel and concrete materials. The construction of this roof involves using a layer of galvanized sheet as a deck underneath, with reinforcement and concreting applied on this robust layer.

Steel deck sheet:

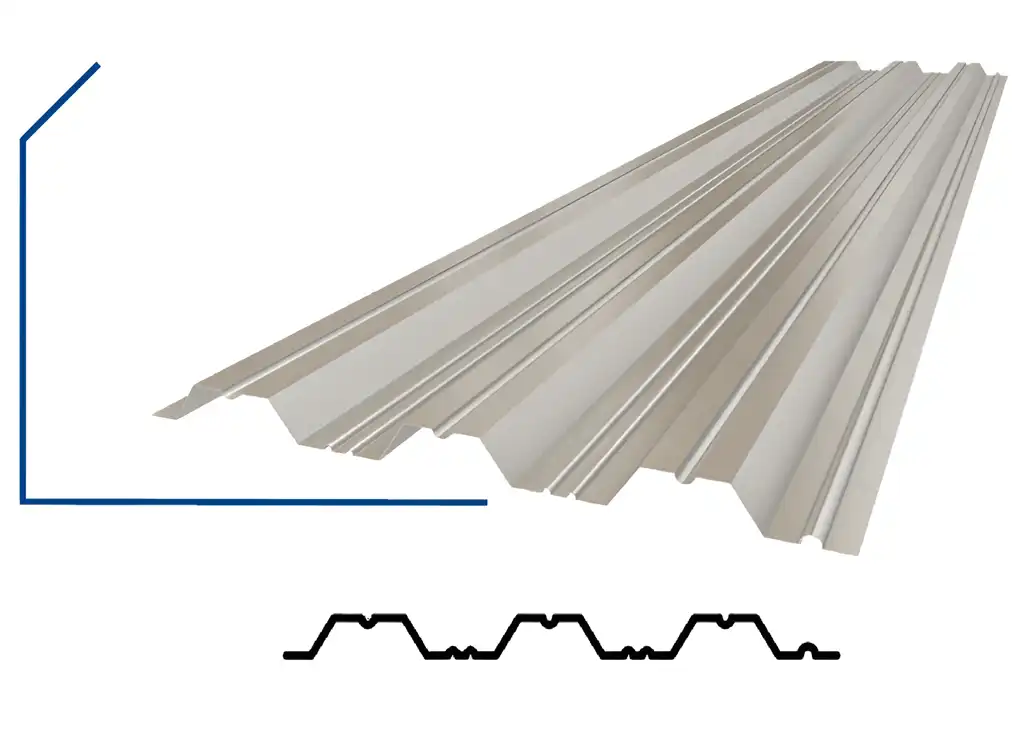

This sheet is made from galvanized steel with thicknesses ranging from 0.8 to 1.2 mm and features a ribbed trapezoidal design created during the forming process through methods like cold rolling in devices such as roll forming. This type of sheet is utilized as a permanent formwork (mold) in the roof because of its lightweight and high strength. A steel deck not only enhances the aesthetic appeal of the lower roof section but also extends the spans of the sub-beams without the need for jacking and piling.

Applications of steel deck roofs:

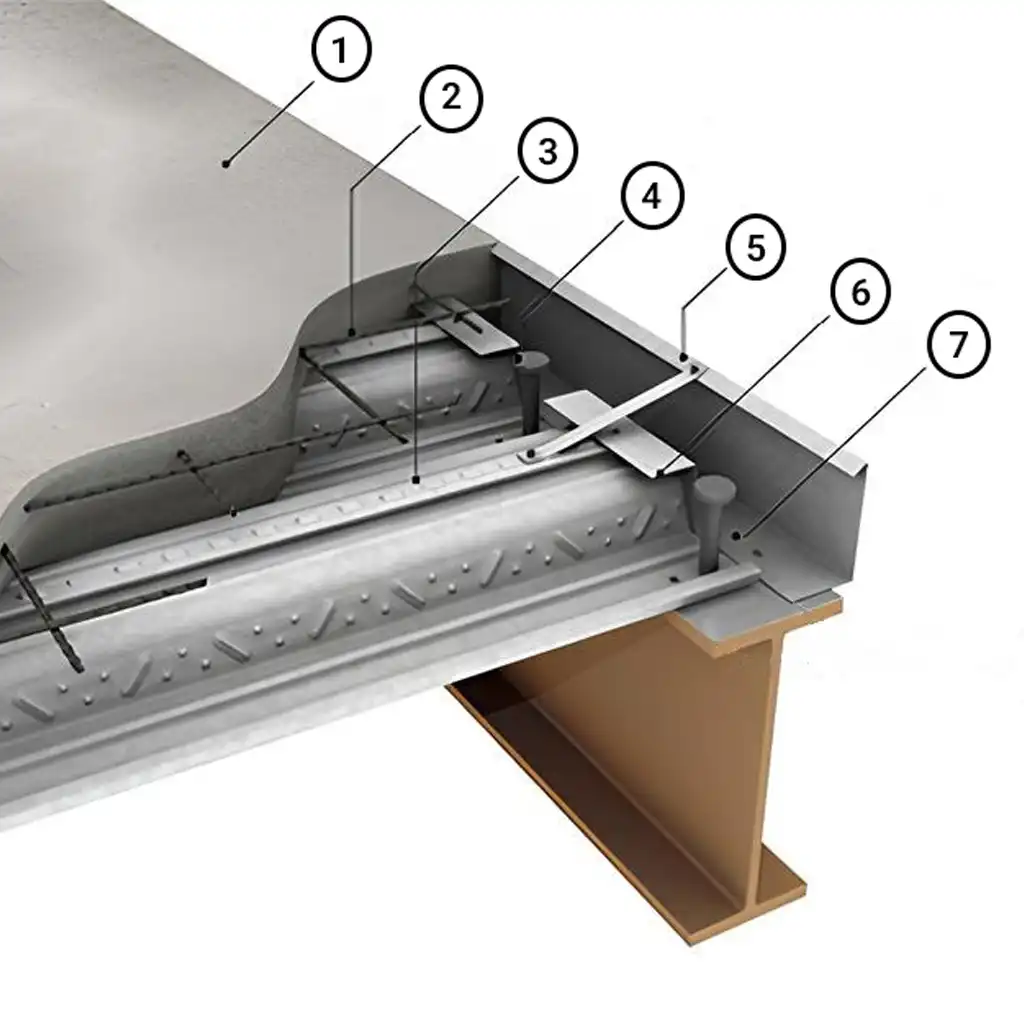

Components of a steel deck system:

- Concrete slab

- Reinforced mesh (rebar)

- Steel deck profile

- Shear stud

- Edge trim and harness strap

- End cap

- Stabilizer (according to project specifications)

Steel deck roof installation:

- Galvanized sheets are connected to each other by screws, rivets, or welding to form a deck.

- The deck is subsequently attached to the main beams through the use of steel nails or electric arc welding. At this stage, the galvanized sheet is secured, the flashings are put in place along with the harness strap, and the steel nails are driven in using a specialized machine.

- The last stage is dedicated to reinforcement and concreting.

Advantages of steel deck roof:

- Compliance with the Iranian national building regulations standards in production and installation:

This approach involves designing and producing the sheet sections in compliance with national building regulations and standards. Furthermore, all calculations and implementation methods of this approach are meticulously in compliance with the relevant regulations.

- ✔High resistance to fire and earthquake: Steel roofs are resistant to fire and do not burn, thanks to the use of galvanized metal sheets. Additionally, because of their lightweight nature and the interconnection among the components, they tend to collapse more gradually during an earthquake, resulting in less damage if they do fall.

Very light weight:

- Galvanized sheets utilized in the construction of sections are significantly lighter than other materials. The weight of a single square meter of galvanized sheet cannot be compared to the equivalent weight of beams and blocks. This feature additionally decreases the weight of the skeleton and the size of the foundation.

-

- Using less concrete without sacrificing quality:

The use of this method results in a reduction of approximately 10 to 15 percent in concrete consumption. This not only leads to a substantial reduction in the overall weight of the structure but also saves more time and cost. Due to the absence of sap leakage and penetration, along with the retention of adequate water and humidity levels, the process of curing concrete is simplified and cost-effective. Therefore, this leads to the production of higher-quality concrete.

- Using less concrete without sacrificing quality:

- High resistance to fire and earthquake:

Steel roofs are resistant to fire and do not burn, thanks to the use of galvanized metal sheets. Additionally, because of their lightweight nature and the interconnection among the components, they tend to collapse more gradually during an earthquake, resulting in less damage if they do fall.

- Very light weight:

Galvanized sheets utilized in the construction of sections are significantly lighter than other materials. The weight of a single square meter of galvanized sheet cannot be compared to the equivalent weight of beams and blocks. This feature additionally decreases the weight of the skeleton and the size of the foundation.

- Using less concrete without sacrificing quality:

The use of this method results in a reduction of approximately 10 to 15 percent in concrete consumption. This not only leads to a substantial reduction in the overall weight of the structure but also saves more time and cost. Due to the absence of sap leakage and penetration, along with the retention of adequate water and humidity levels, the process of curing concrete is simplified and cost-effective. Therefore, this leads to the production of higher-quality concrete.

- Shorter duration of project completion:

Galvanized sheets, characterized by their low weight and large dimensions, are utilized in the construction of this type of roof. Evidence has demonstrated that their installation can be up to eleven times quicker than that of other roofs. Some projects have even achieved an outstanding record of delivery of 500 to 1000 m2 of this type of roof in a single day.

-

- No need for piling: Installing safety supports beneath the roof surface to avert deformation and collapse of the concrete until it achieves adequate strength is referred to as piling. Piling is a challenging and lengthy process. The use of steel deck roofs eliminates the need for this laborious process.

- Greater operational safety: This method minimizes the risk of injury to workers during the installation operation.

- Simultaneous concreting of multiple roofs: In methods that utilize beams and blocks, the concreting of other floors cannot proceed until the completion of one floor. The use of steel deck roofs allows for the simultaneous concreting of all floors, which can greatly increase the execution speed.

-

- Reduced human errors: When it comes to implementing methods like beams and blocks, one often faces a plethora of human calculation and execution errors. However, with steel deck roofs, the risk of human errors is significantly minimized thanks to the streamlined industrial production and execution of most projects.

- Easy transportation and maintenance: These sheets are lightweight and large, making them easy to transport in a very short time. Their design and size allow us to accommodate a large quantity of them within a compact area.

No need for molding, tensile rebar, etc.: This process leads to a reduction or complete elimination of various materials and methods, including molding, certain sub-beams, tensile rebar, and more. This method causes an increase in the distance between sub-beams in the roof, reaching up to 3 meters, all without the need for piles.

Key considerations regarding the installation of steel deck roofs:

- This type of roof should be installed by skilled and experienced workforces.

- This method is more challenging to implement in concrete skeletons than in other skeletons and necessitates additional precautions.

- As previously stated, this type of roof can be implemented at a very impressive speed. However, all conditions, arrangements, and preparations must be meticulously organized before proceeding to the implementation.

- One of the key aspects of putting this method into action is the potential for the panels to vibrate. If skilled professionals perform this method under the fundamental principles of building engineering, it is possible to significantly minimize the impact of severe vibrations.

- Keeping the right distance between the sub-beams, ensuring the steel sheet is just the right thickness, and sticking to the standard height of the deck can work wonders in minimizing vibrations.

- Even though the sheets are galvanized, there is still a risk of scratches and scuffs during installation and welding, leading to the dreaded metal corrosion.

- Every single metal surface must be meticulously examined following installation to ensure everything is just right. In certain situations, raw zinc finds its way into the metal core of the roof, enhancing the panels’ ability to resist corrosion and stand the test of time.

- The supervisor must keep a watchful eye on every single welding joint to ensure everything is up to par.

Furthermore, the National Building Regulations outline the proper ways to calculate the geometric properties of roofs, as well as the typical sections of the sheets, the properties of the materials needed for implementation, and more. It is critical to note that these technical regulations allow one to ascertain the properties of steel deck roofs as well as the loadings applied to each section type.

Load bearing of steel deck roofs:

This roof design is primarily utilized in the construction of buildings that require a significant load-bearing capacity.

The load-bearing capacity of this type of roof is determined by the thickness and height of the walls, the sheet-forming conditions, and the amount of sand and cement in the concrete.

A steel roof can typically support a maximum weight of around 1,200 kg (including both dead and live loads), contingent upon the thickness of the sheet and the spacing of the beams.

Length of steel deck roof openings:

The spacing of the sub-beam openings in this roof exceeds that of other roofs. The length of the opening in the steel deck roof is established based on the thickness of the deck sheet to mitigate vibration. For extended distances, the sheet’s thickness should be adjusted accordingly. For an opening ranging from 2.50 to 2.60 meters, a sheet with a thickness of 0.9 mm is advisable, while a thickness of 1 mm is suitable for openings between 2.60 and 3 meters.

Price of steel deck roofs:

The precise estimation of costs for each component of the building stands as a crucial technical element in the construction process. Alongside strength, quality, durability, construction speed, and beauty, the importance of economy and financial cost optimization cannot be overlooked. Patterned galvanized sheets find application in the construction of steel deck roofs. The final price of steel decks is determined by the current price of galvanized sheets and the additional costs associated with patterning them. In addition, the cost of the equipment utilized in the implementation of this roof, e.g., galvanized flashings, harness straps, steel studs or nails, and thermal rebar, significantly affects the final price.

Price of steel decks:

Borj Pooshesh Apadana Engineering Technical Group is dedicated to delivering high-quality products. Therefore, we offer different types of steel decks with a wide range of lengths and thicknesses at competitive prices. Please contact our sales team to place an order or inquire about the pricing of steel decks.