Shadowline sheet

A new material being utilized in roof construction is the Shadowline galvanized sheet. This sheet is crafted from painted galvanized material and boasts numerous applications thanks to its striking beauty. This application of this sheet, particularly on the roofs of industrial centers, has transformed the dryness and coldness of these environments into a refreshing and aesthetically pleasing atmosphere. The Shadowline sheet is useful in various areas of buildings, such as walls.

Shadowline sheet, where elegance meets durability:

The roof serves as a crucial element of any building’s design. The roof serves to shield various elements of the building from factors such as rain, heat, cold, and sunlight. The materials utilized in roofing have undergone continuous change and development. One of the innovative materials utilized in roofing for structures is Shadowline galvanized sheet. This article aims to provide valuable insights into Shadowline painted galvanized sheet.

Applications of Shadowline sheet:

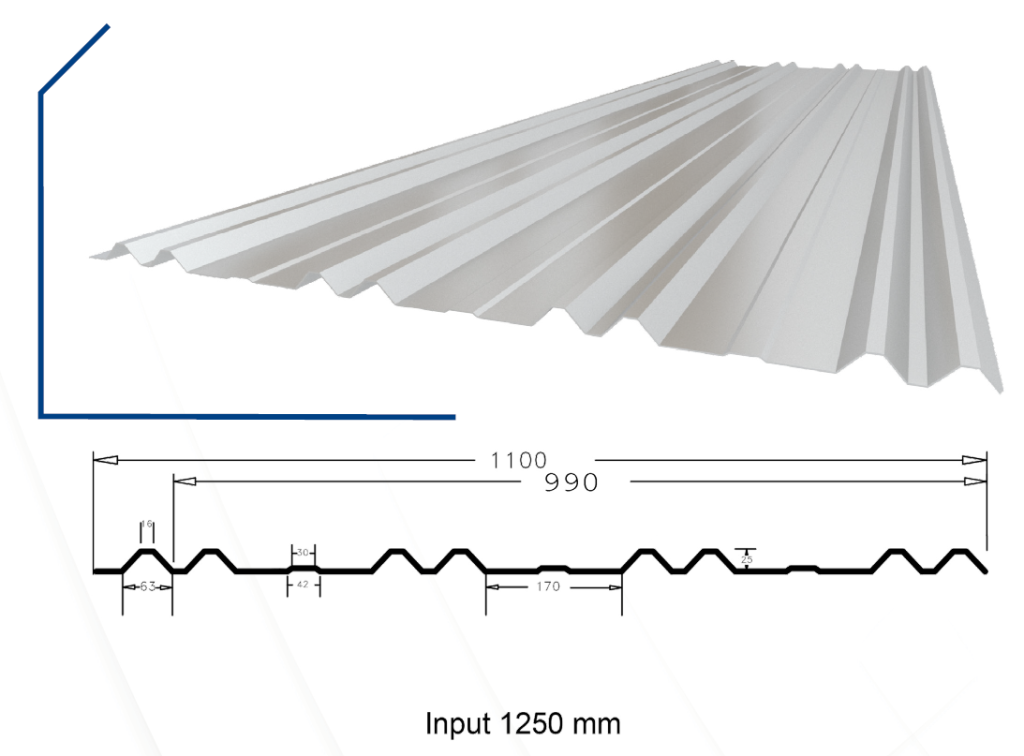

| Technical specifications: | |

| Sheet width | 1,250 mm |

| Post-forming sheet width | 1,010 mm |

| Useful width | 990 mm |

| Thickness | 0.4-0.9 m |

| Type of sheet | Painted galvanized |

Features and dimensions of Shadowline sheets:

- This sheet is available with thicknesses ranging from 0.3 to 0.7 mm and widths of 100 and 125 cm.

- These sheets generally weigh about 5 kg, but their weight changes based on their length, width, and thickness.

- The beauty, lightness, and affordability of these sheets make them a popular choice for most sloping roofs.

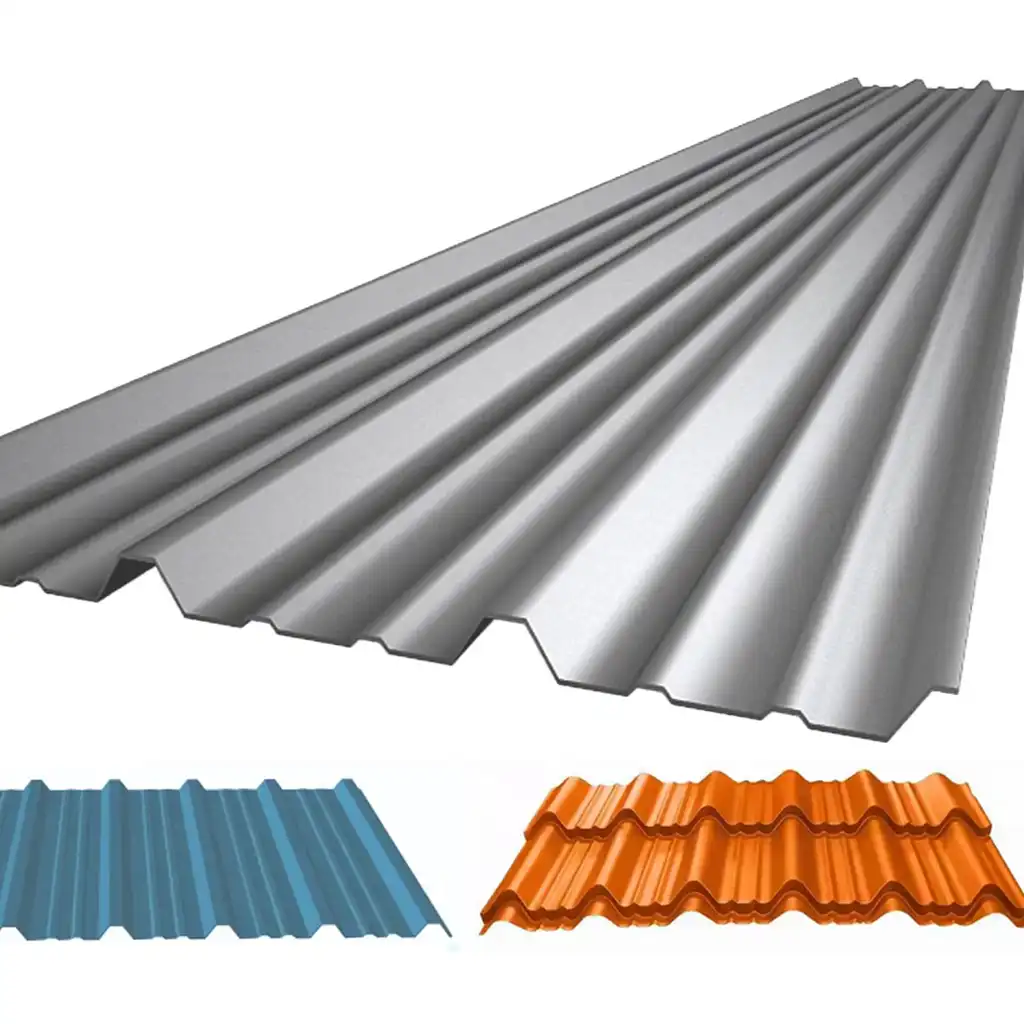

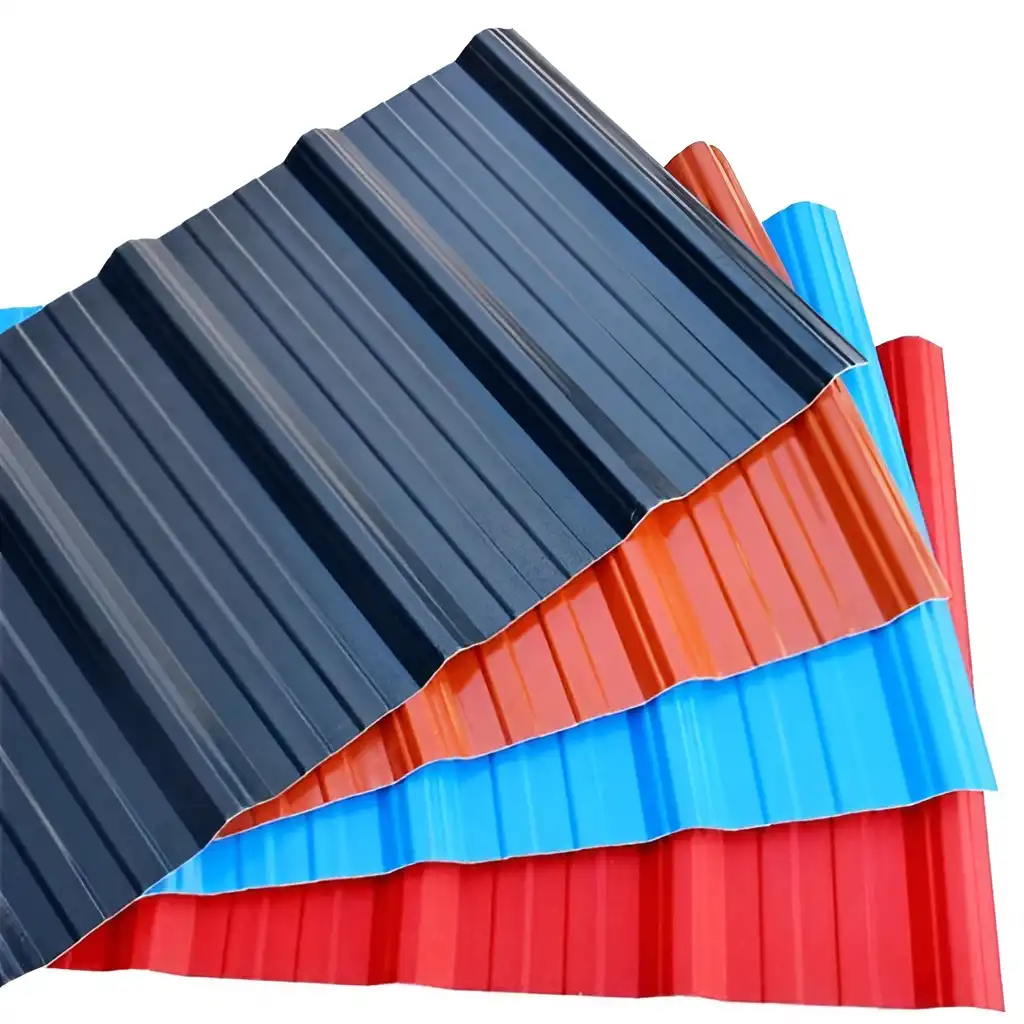

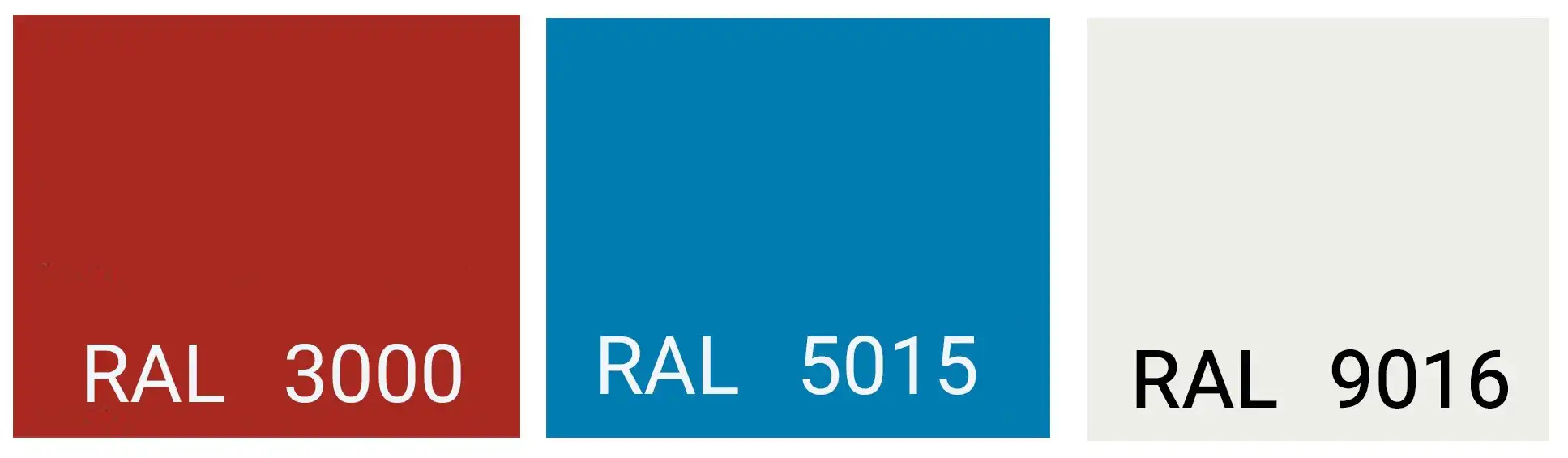

- Shadowline sheets are available in a wide range of colors such as white, red, gray, yellow, blue, and green.

- These sheets are fastened to one another with screws and are installed in an overlapping manner.

- Galvanized sheets offer moisture resistance; however, when used on roofs, it is advisable to incorporate insulating materials like glass wool, XPS foam, or EPS polystyrene to fill the gaps between them.

Advantages of Shadowline gable sheets:

1-Light weight:

- Due to their heavy weight, traditional construction materials reduce the lifespan of buildings and cause greater damage during earthquakes. Shadowline sheets are very lightweight due to their dimensions. Undoubtedly, its lightness does not compromise its strength. The lightweight design facilitates the transportation of Shadowline roof sheets from the factory to the project site, as well as their transfer to the top of the building, resulting in reduced costs.

2-Resistance to moisture, rust, and corrosion:

- Due to their susceptibility to moisture, metals are typically covered with protective materials. Galvanized sheet refers to steel that has undergone a coating process with zinc. Galvanized sheets provide excellent resistance to moisture and rust. The essence is that the galvanized coating infiltrates the base metal and is regarded as a cathode. Even if some of the coating is lost, the steel remains resistant to rust and corrosion.

3- Painted:

- Shadowline sheets come in an extensive range of colors. The color coating not only adds a unique level of aesthetics to these sheets but also enhances their durability against damage from corrosion, moisture, and other factors. This product features a coating of furnace paints. This painting technique not only effectively prevents color change and preserves the appearance of sheets but also increases their resistance to scratches and damage even under the harshest weather conditions.

4-Corrugated

- Painted Shadowline sheets are shaped into a variety of designs, such as trapezoidal, sinusoidal, or louvered. The corrugated design, achieved through the bending process, offers benefits including enhanced aesthetic appeal, improved water and snow transfer, and increased strength. Moreover, corrugated sheets possess significantly greater strength compared to flat sheets.

5- High durability:

- Shadowline sheets are made from painted galvanized metal sheets. Therefore, they can endure different weather conditions for an average of 20 to 30 years or even longer.

6- Easy and quick installation:

Painted galvanized Shadowline sheets are manufactured in larger sizes and lower weights than alternative materials. As a result, they can be installed

7- Compliance with national and international standards:

- sheets are produced following the latest national and international standards. These sheets are produced with exceptional quality utilizing the latest global technologies, resulting in a significantly low cost for repair and maintenance.

8- Price of Shadowline gable sheets:

- Employers and project managers always prioritize the optimization of financial resources and expenses. The use of Shadowline sheets will result in cost savings for the following reasons: their exceptional durability and longevity reduce replacement and repair expenses; easy and rapid installation leads to lower labor costs, faster project preparation, and a rapid return on investment and profitability; the light weight of these sheets facilitates their easy transportation and reduces transportation expenses, without the need for equipment such as cranes and specialized machinery.

9- High integrity:

- Painted Shadowline sheets exhibit resistance to bending and twisting, ensuring they remain unbroken.

10- Reduced fire damage:

- Due to their integrity and lightweight nature, structures constructed with Shadowline sheets cause reduced harm and damage to their occupants during fire and earthquake. The walls and roofs of such structures exhibit enhanced strength and a lightweight design, reducing the risk of collapse and minimizing damage.

Price of Shadowline sheets:

Apadana Borj Pooshesh Engineering Technical Group is dedicated to delivering high-quality products. Therefore, we offer different types of Shadowline sheets with a wide range of lengths, thicknesses, and colors at competitive prices. Please contact our sales team to place an order or inquire about the pricing of Shadowline sheets.

Shadowline galvanized steel sheet colors

Standard Colors

Special Colo