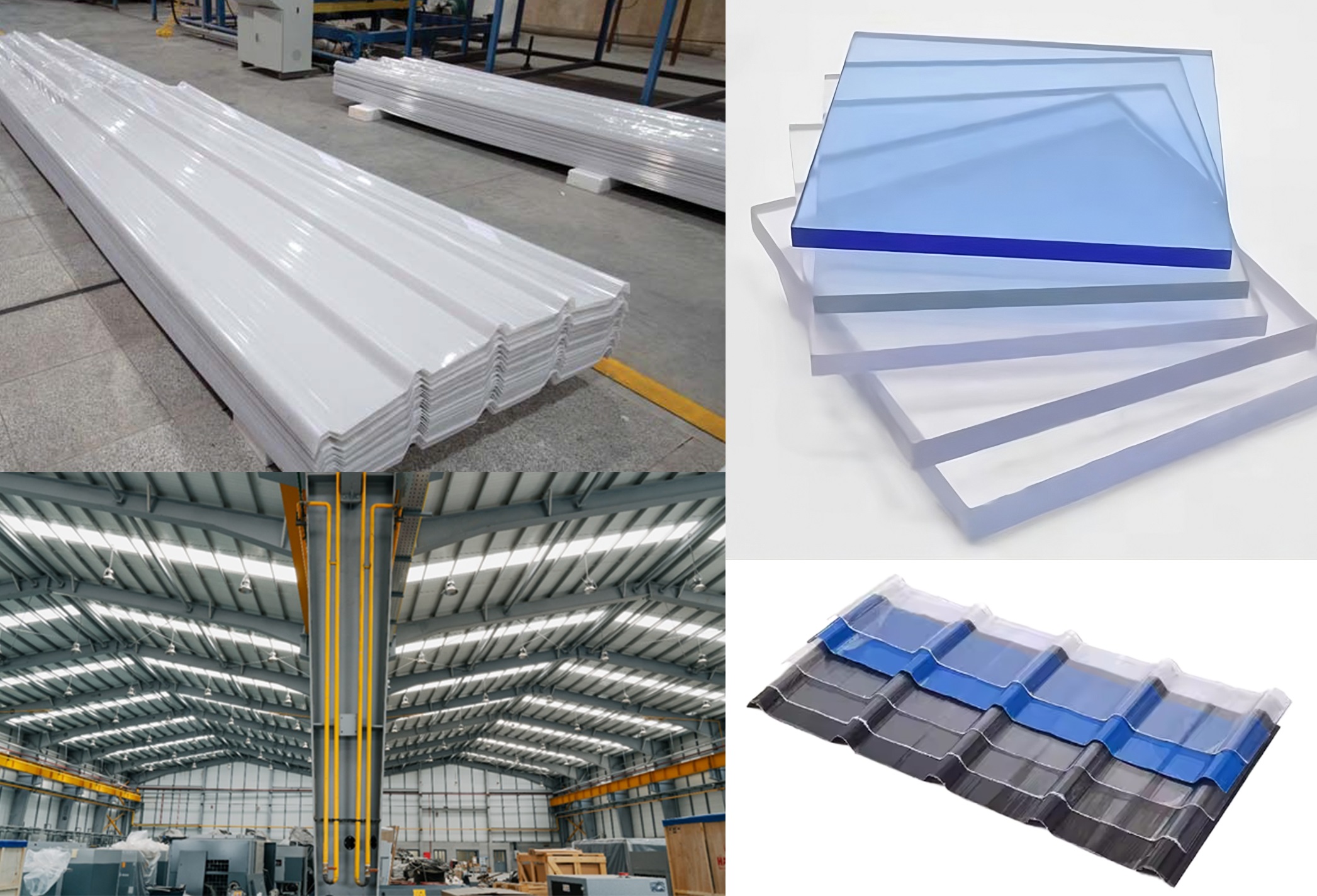

Price of three-wall and five-wall polycarbonates

Borjpooshesh Apadana Manufacturing and Engineering Company utilizes state-of-the-art production technologies and the expertise of its engineering team, combined with high-quality raw materials, to manufacture this product and deliver it to customers at the most competitive price. For order placement and price inquiries regarding three-wall and five-wall polycarbonates, you can contact the sales experts at Borjpooshesh Apadana Manufacturing and Engineering Company. We will be pleased to assist you.

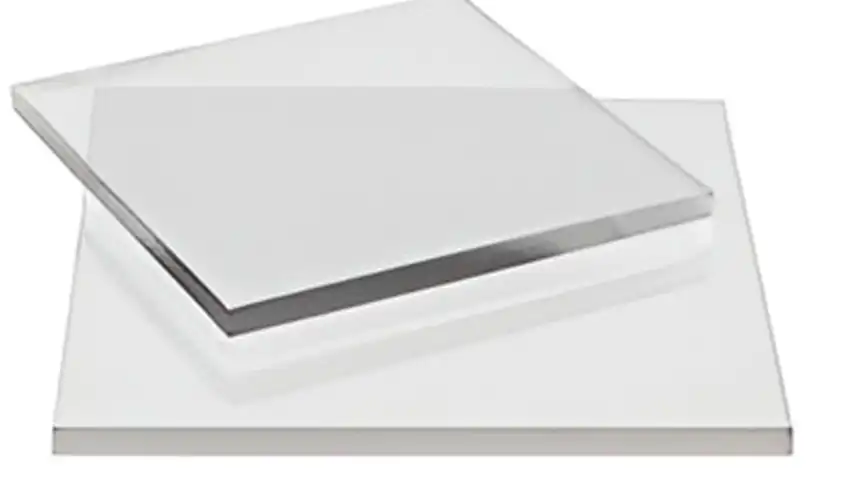

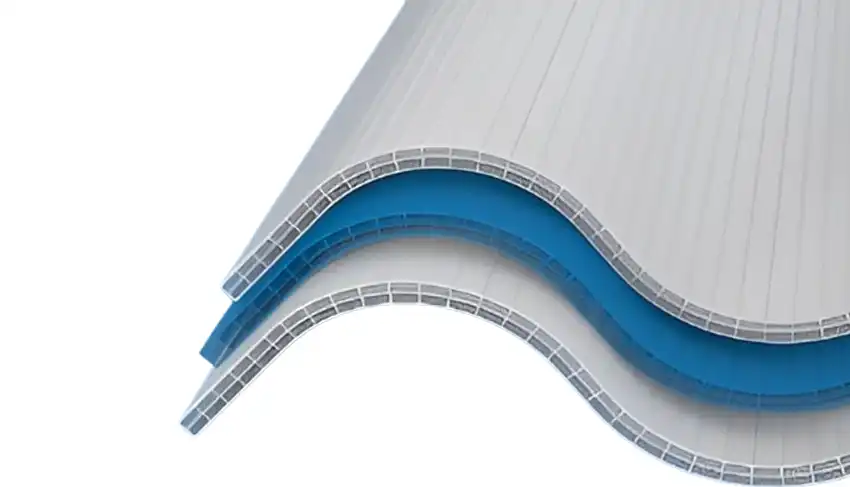

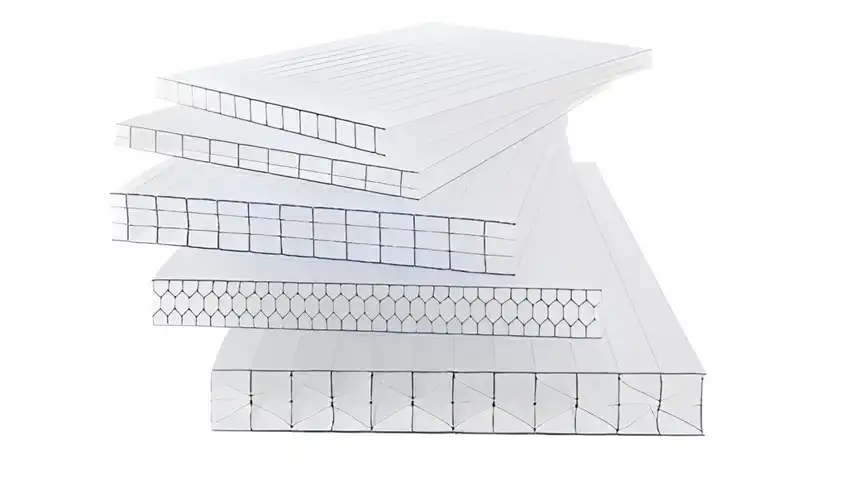

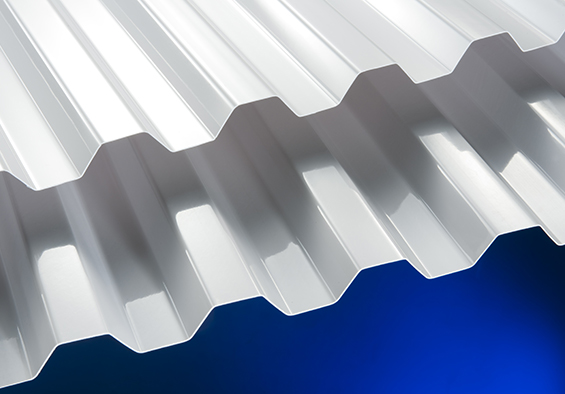

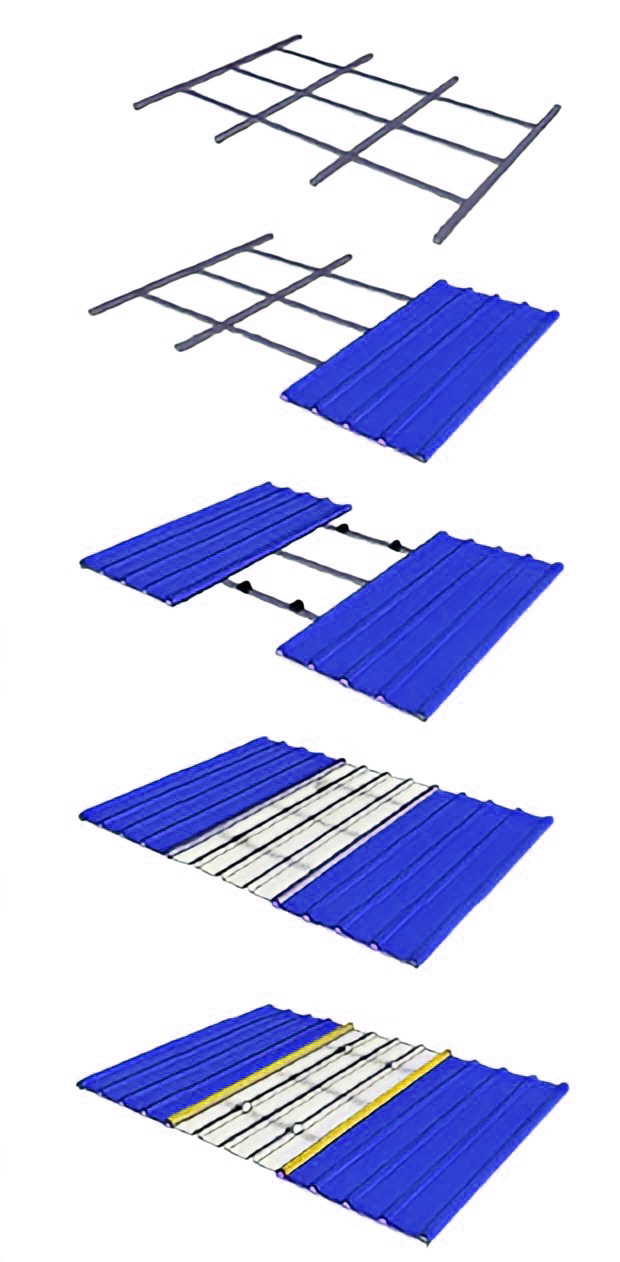

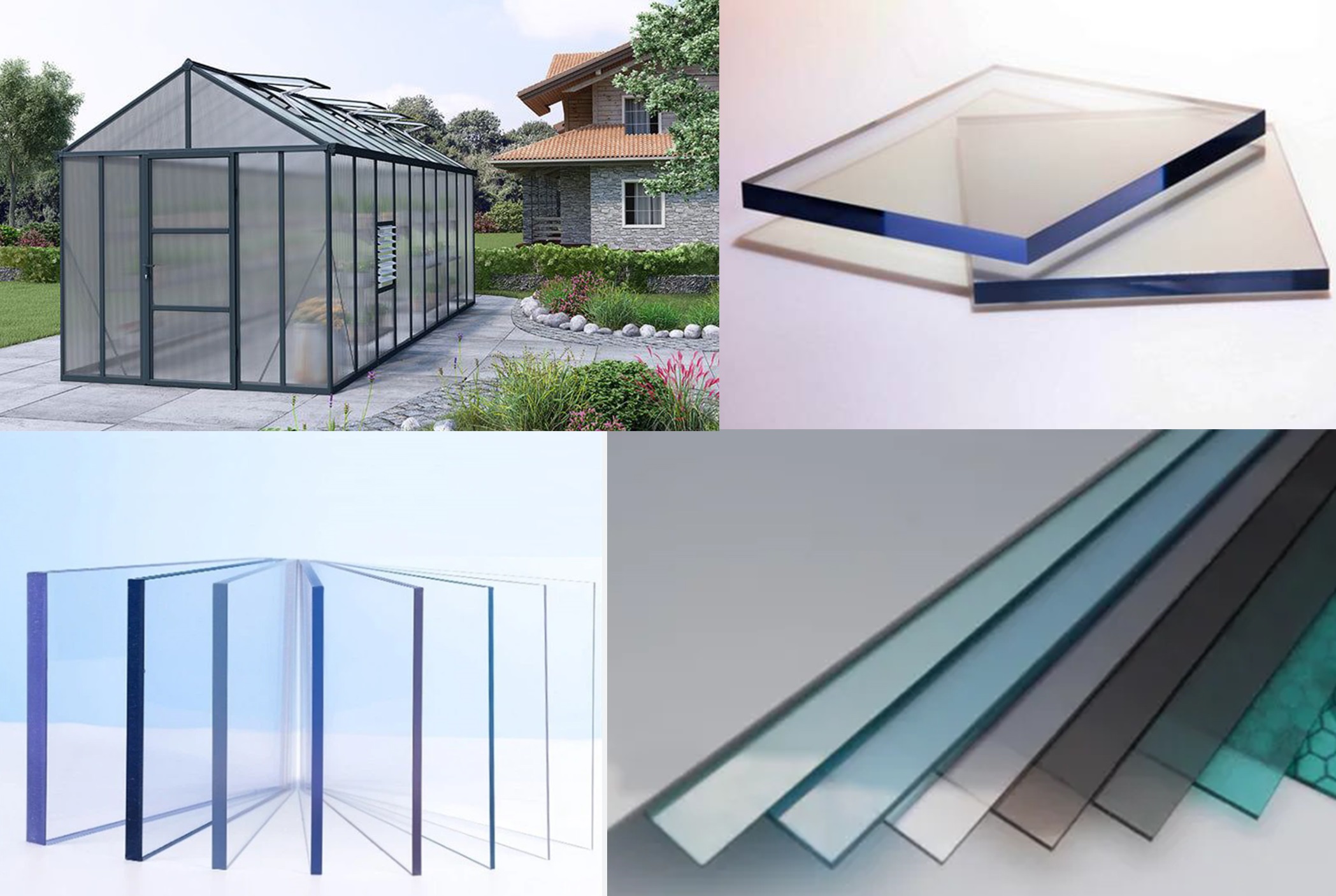

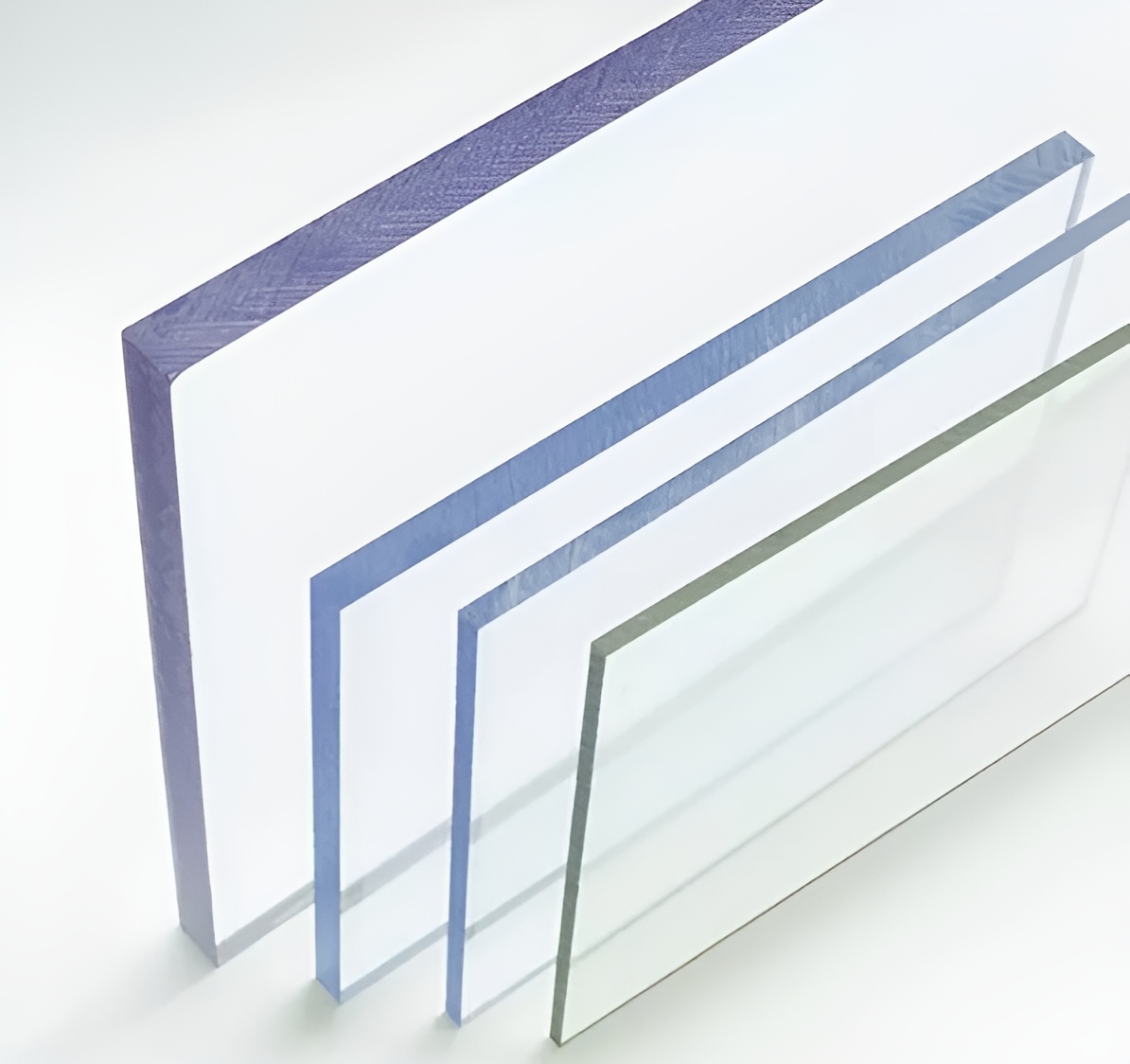

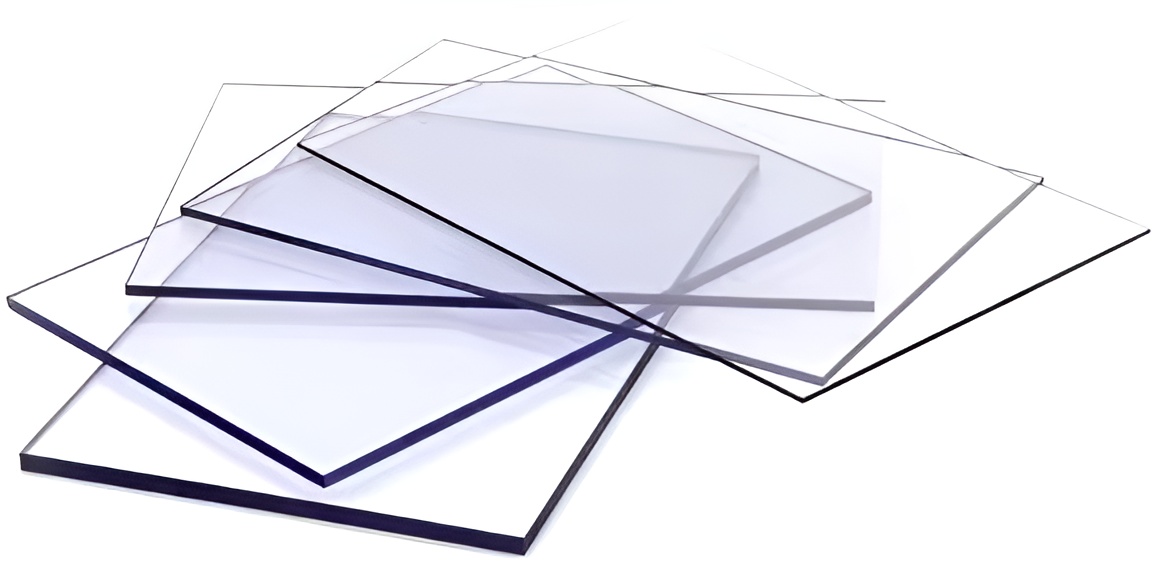

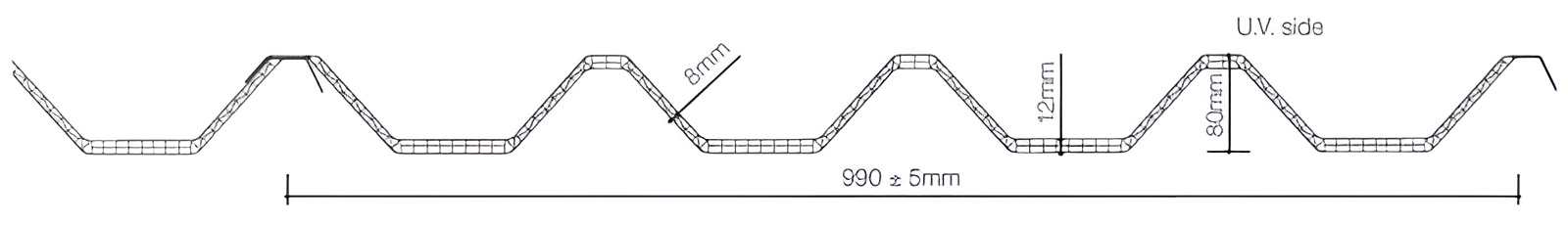

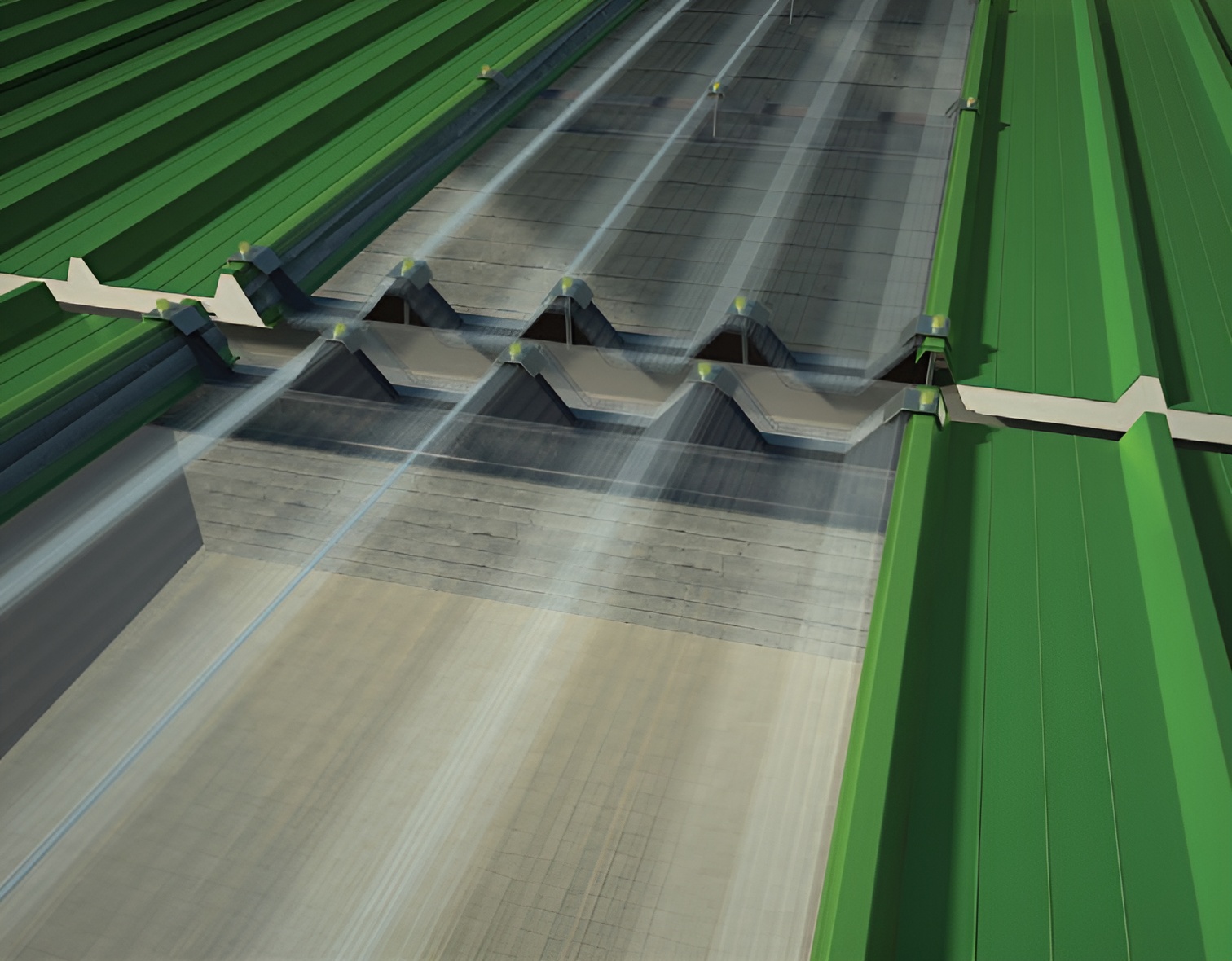

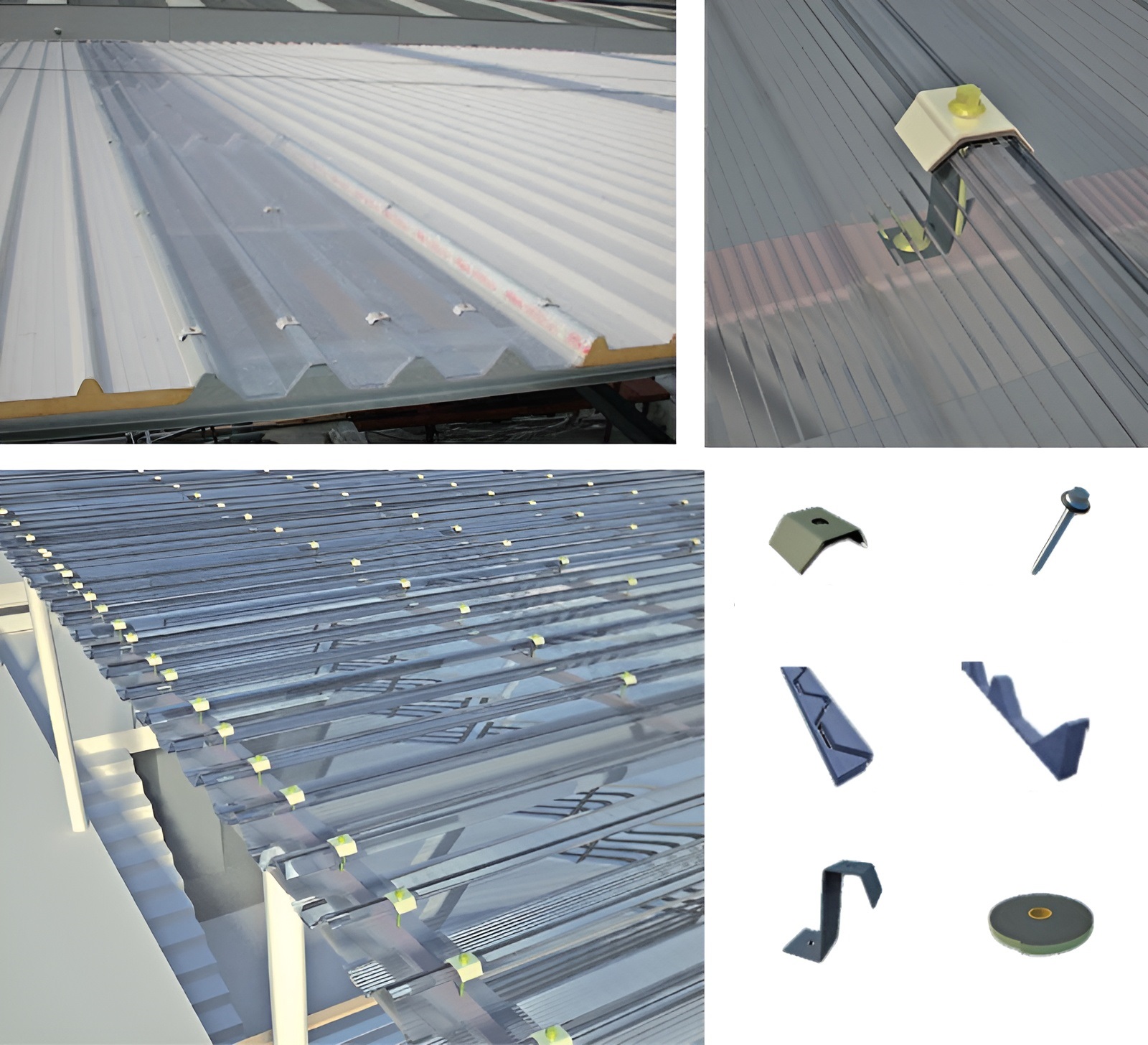

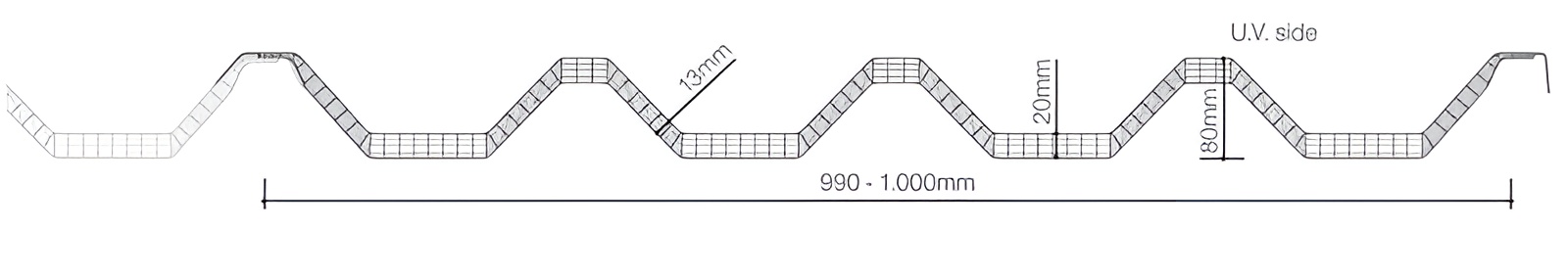

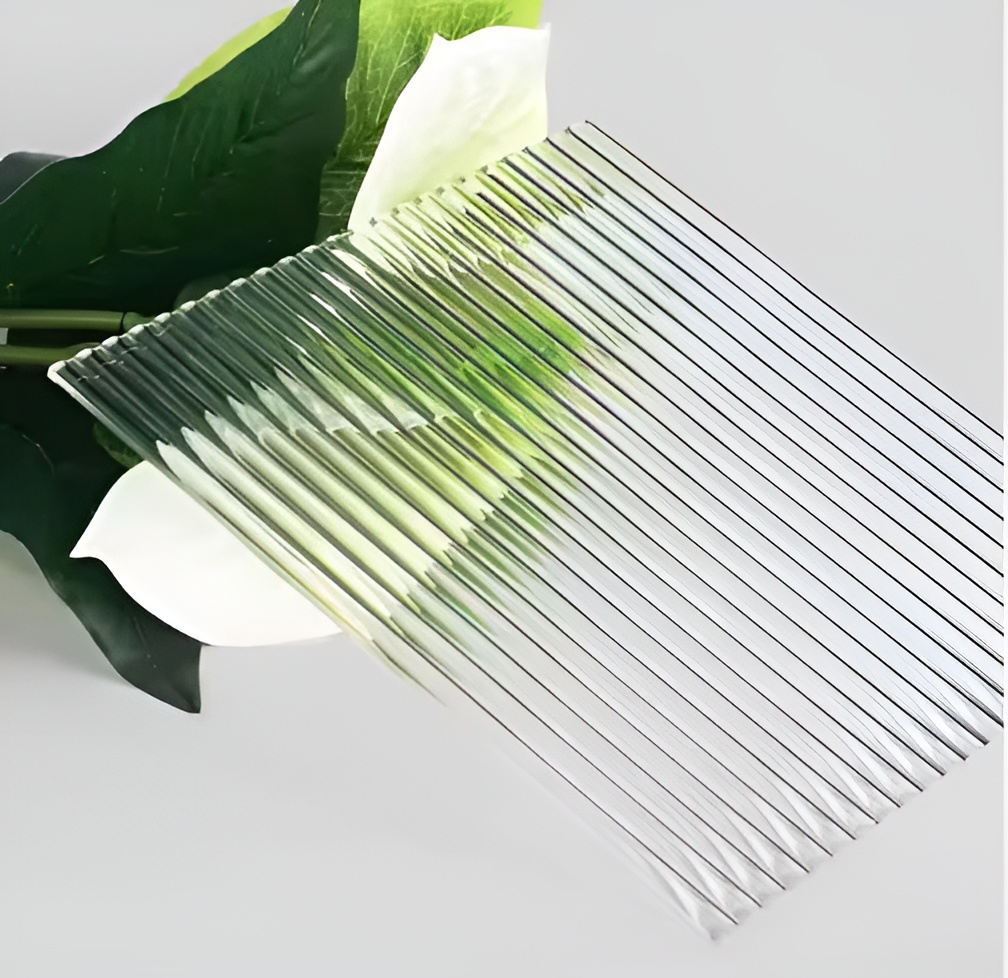

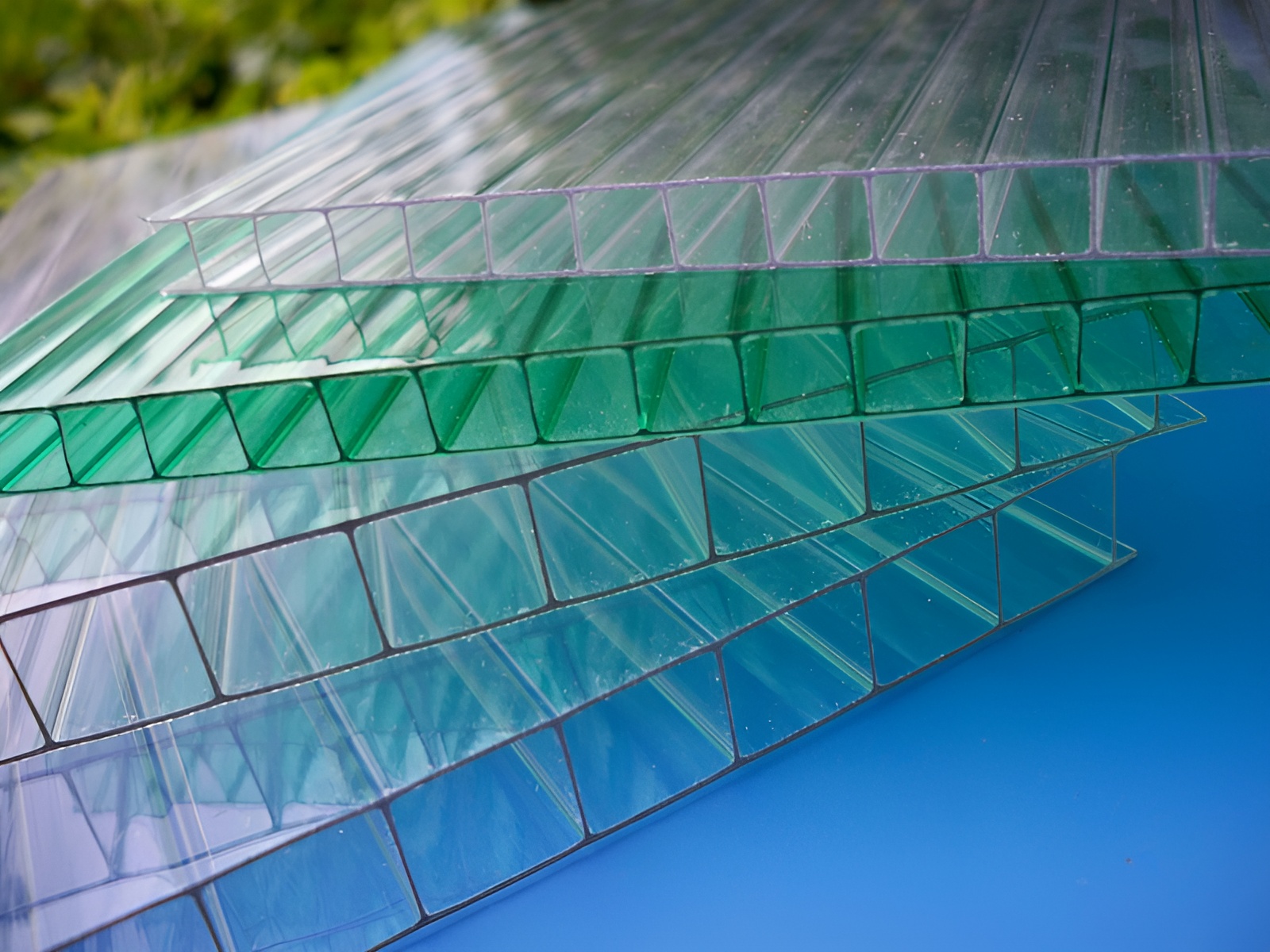

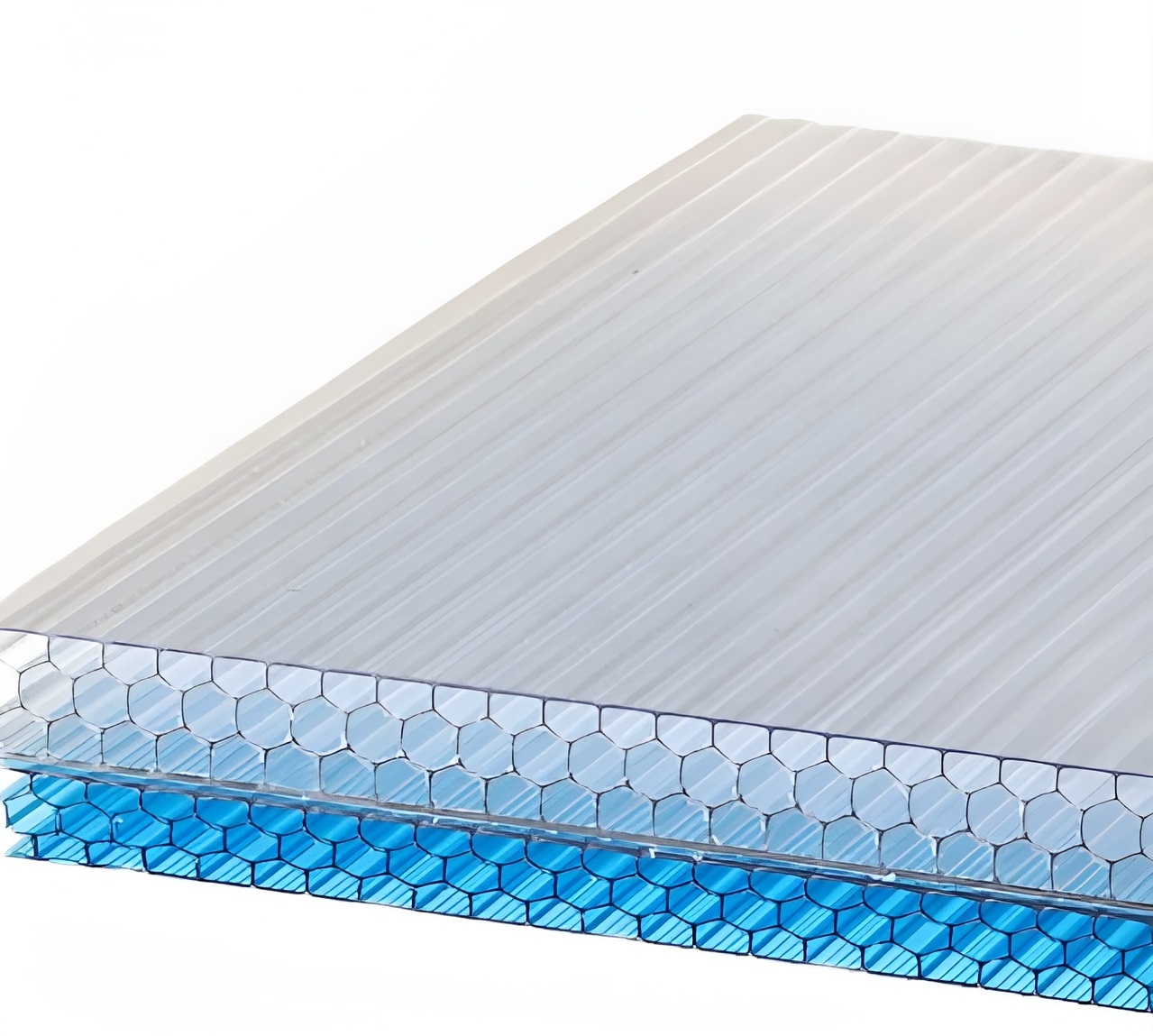

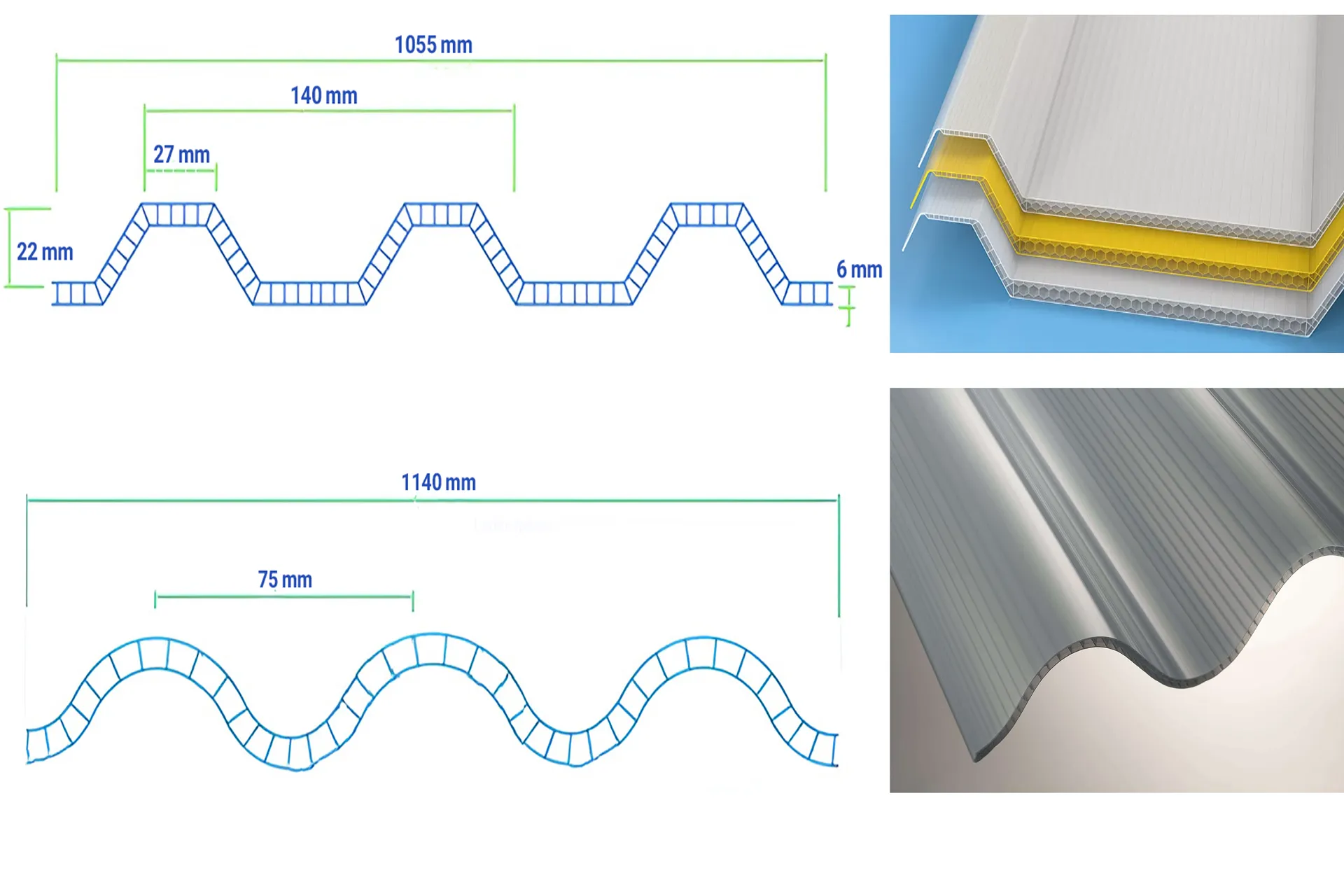

Multi-wall polycarbonate sheets, including the hollow-sheet polycarbonate variant, are available in a diverse range of colors, coatings, and structural configurations. These polycarbonate sheets provide numerous advantages, including a lightweight design, ease of installation, high impact resistance, superior thermal insulation, sustained light transmission, and robust protection against UV radiation and condensation. For instance, in football stadiums, this type of polycarbonate sheet is utilized to facilitate innovative glazing solutions with straightforward installation. Additional benefits of polycarbonate hollow sheets include superior photosynthetic light transmission compared to glass and polyethylene films, high flexibility and adaptability to curved structures, extended service life with UV-resistant properties to prevent yellowing, effective thermal regulation across seasonal variations, protection against thermal shock for plants, cost-effectiveness, and exceptional resistance to moisture. Polycarbonate hollow sheets are available in thicknesses of 6, 8, 10, 12, 14, and 16 mm, with standard dimensions of 6000 mm x 2100 mm.