Gutter:

The gutter, an essential part of the roof

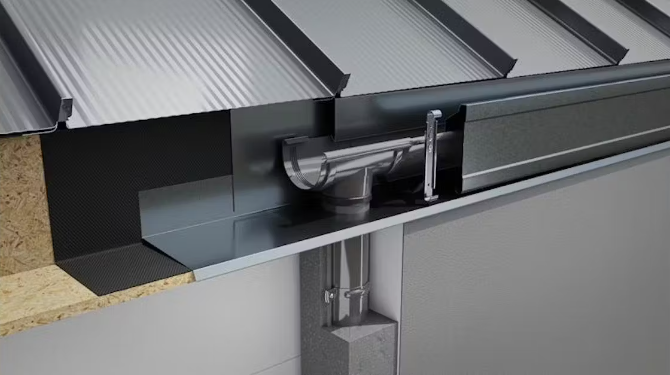

In the construction industry, a wide array of tools and equipment is consistently utilized. Each of these pieces of equipment possesses its own efficiency and application. One type of equipment utilized across different industries is the gutter sheet, which serves to create a downward water path. The primary application of the gutter sheet lies in the foundation, sealing, and grading of gutters. The use of gutter sheets undoubtedly offers numerous advantages and benefits. A gutter is a sheet positioned at the edge of sloping roofs, designed to effectively channel rainwater and snow away from the structure’s exterior. Gutters serve the purpose of managing, gathering, and directing rainwater from the roof downward. The gutter serves as a crucial component of the roofing system for any building. This component is crucial for the structural integrity and the comfort of its inhabitants. The roofs of industrial centers, sheds, and the majority of structures constructed with sandwich panels are designed in a gable shape. Gutters are utilized to effectively manage rainwater and snow on gable roofs. Here we will explore the application of gutters in sandwich panel roofs.

Gutter production process

Importance of gutters:

Construction experts consider a wide range of factors when designing roofs, e.g., the geographical location of the building, humidity levels, and rainfall amounts, among others. In areas with significant precipitation, roofs must be constructed with a sloped design. The gutter plays a key role in the functionality of sloping roofs. As its name implies, this roof component helps transfer water from the roof to the ground. Since most rainwater flows through the gutters, choosing the right model is crucial. The reason behind this is that when it rains or snows, water can collect on the roof. This water can then seep into the structure, potentially damaging the walls and ceiling as well. Therefore, gutters or prefabricated water channels are used to mitigate this issue. In fact, gutters function as a water channel, directing excess water outward. This product is available in a variety of colors and thicknesses.

Different types of galvanized gutter for gable roofs:

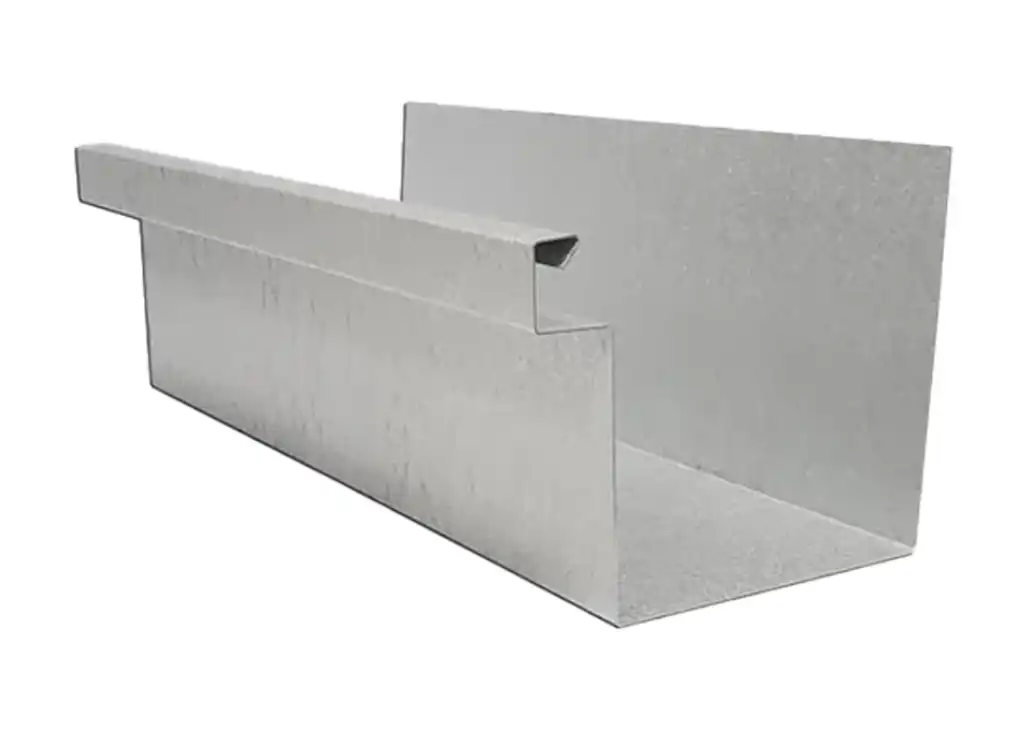

Box (square) gutter:

The box, square, or pot model is crafted in rectangular and square forms, featuring a thickness of 1.5-2 mm and available in lengths of 3 and 6 meters with various widths. This model is the most commonly utilized type of gutter, suitable for all varieties of gable roofs. The straightforward design, along with the flexibility in sizes and dimensions of this model, as well as the adjustable angle of its walls, enables the designer and installer to fit the product in places with varying dimensions. The precise dimensions and measurements in this model provide significantly easier and more accurate welding and sealing than other models. In this model, gutter pipes and specialized funnels are utilized to direct water to the ground. This model features both small boxes and large boxes. Here you can see a schematic view of two examples of this model of gutter.

London (circular) gutter:

This model features a circular design. Gutter sheets enhance the appearance of roof edges, manage the flow of rain and snow, and safeguard the roof panels. Painted galvanized sheets are occasionally utilized in the production of this model to enhance its aesthetic appeal and ensure compatibility with other structural components. The manufacturing of this product involves the use of galvanized sheets with a thickness ranging from 0.4 to 5 mm and a length of approximately 3 meters, as well as painted galvanized sheets with a thickness between 0.4 and 0.6 mm, measuring 2 and 2.5 meters in length.

Wicked (Swedish-Hidden) gutter:

This model represents the earliest form of galvanized gutter, serving as the foundation for the design of the London model. This product offers significant benefits, including an affordable price and a straightforward, rapid installation process. The wicked section of this gutter is folded and connected to the gable roof.

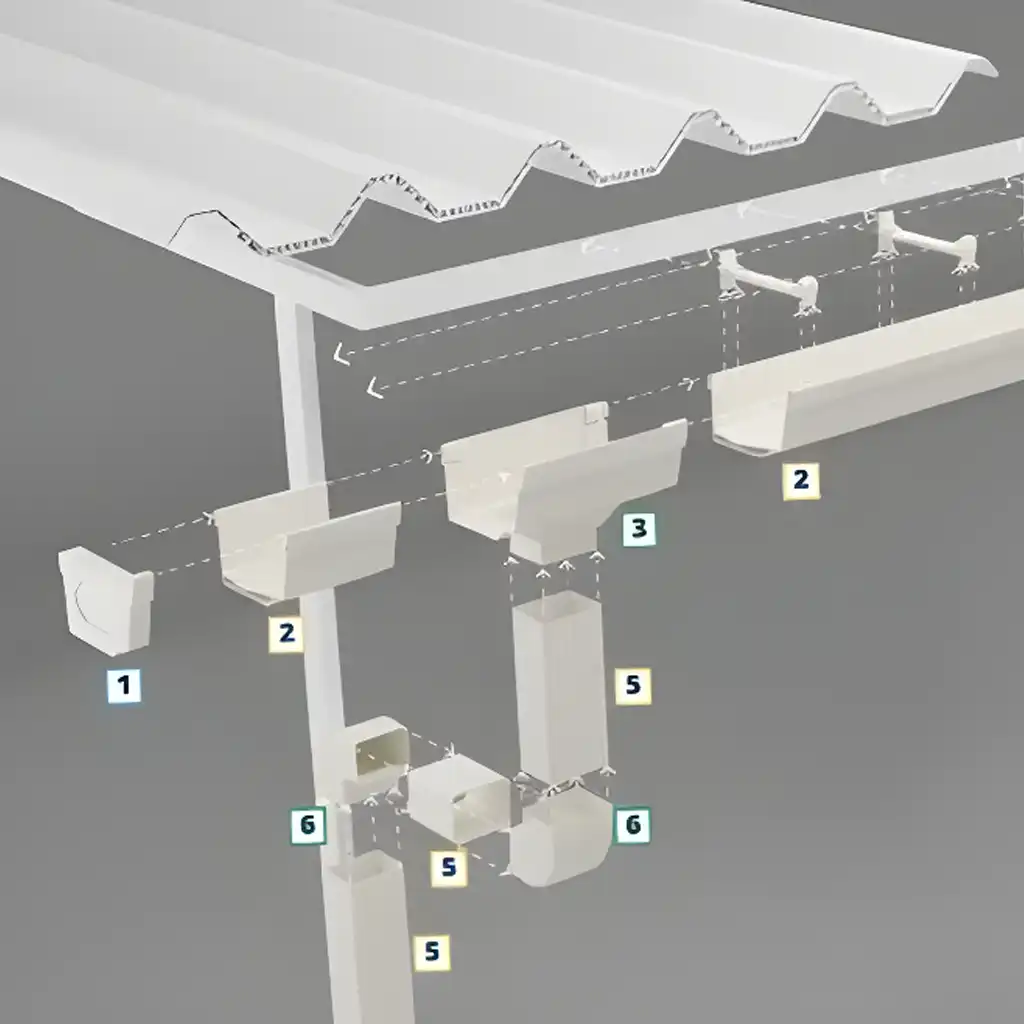

Components of a gutter system:

- End cap

- Gutter

- Downspout (funnel)

- Gutter guard

- Gutter

- Elbow

Apadana Borj Pooshesh Engineering Technical Group employs the latest techniques and state-of-the-art industrial machinery, along with premium raw materials, to manufacture top-tier industrial construction products, including gutters. We offer gutters made from premium galvanized steel sheets, available in thicknesses of 1.5 and 2 mm and lengths of 3 and 6 meters.

Technical specification:

| Technical Specifications | |

| Sheet width | 1,250, 600, 1,000, and 500 mm |

| Thickness | 1.5-3.0 mm |

| Length | 1- 6 m |

| Type of sheet | Galvanized |

| Brand | Foolad Mobarakeh |

Key considerations regarding gutter selection:

Since there are various types of gutters, it is recommended to select the most appropriate and optimal option based on the location where you intend to utilize this product. The primary features involved in the classification of gutters encompass dimensions, class, material, design, and more. Galvanized gutters with thicknesses of 50 mm, 60 mm, and 70 mm can be installed and formed into a crescent or rolled arch shape. Therefore, galvanized gutter sheets with thicknesses exceeding 70 mm, which are notably thicker, must be cut and bent into rectangular shapes in workshops, considering the spacing between the structural purlins and the suitable slope percentage.

Features of a standard gutter:

Applications of gutters:

- Roof sandwich panels

- Gable roofs and other types of roof

- A variety of product processing settings, including greenhouses, cattle farms, and poultry farms

- Types of parking lots and parking roofs

- Water flow control in various types of sheds

- Industrial settings and parking lots

- Sidewalks, terraces, roofs, garages, and roof gardens

- Restrooms, swimming pools, and restaurants

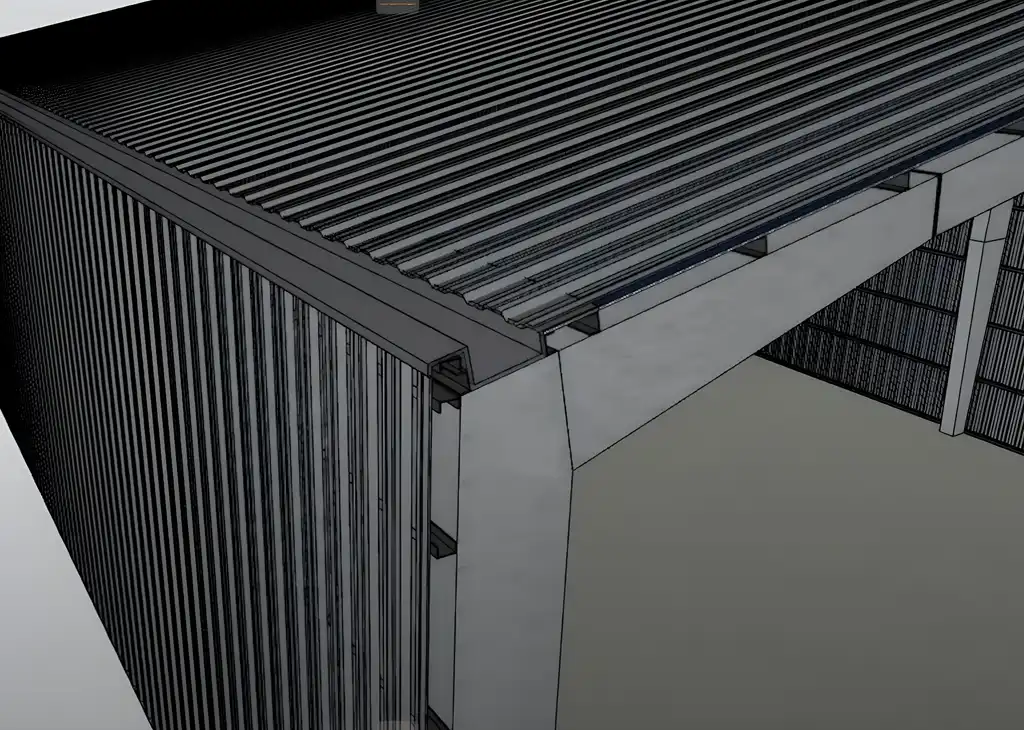

Gutter sheet for sheds:

This type of gutter is the most crucial component used on the roofs of warehouses, sports complexes, factories, and other industrial facilities. Similar to other buildings, it is critical to appropriately divert water from the roof to the exterior to prevent moisture penetration in sheds. The box model of gutters is typically used on the roofs of sheds. It is also used in the following settings:

- Sloping roofs of factories and industrial centers

- Roof of residential units

- Entrance of factories and industrial centers

- Edges of gable roofs and the building skeleton

- Sloping roofs of villas

Key considerations regarding the installation of gutters:

The most important factors that should be considered when installing prefabricated water channels are as follows:

- Channel dimensions

- Location

- Required weight resistance

- Floor insulation method

- Finished floor material

- Flooring limitations

- Location and size of outlet pipes

- Installation of prefabricated structures

For the installation of galvanized gutters, it is necessary to have one set of gutters for each meter. When installing this product, it is essential to utilize specific funnels and gutter pipes to direct water to the ground.

Price of gutters:

Apadana Borj Pooshesh Engineering Technical Group is dedicated to delivering high-quality products. Therefore, we offer different types of gutters in a range of lengths and thicknesses at competitive prices. Please contact our sales team to place an order or inquire about the pricing of gutters.