Flashing:

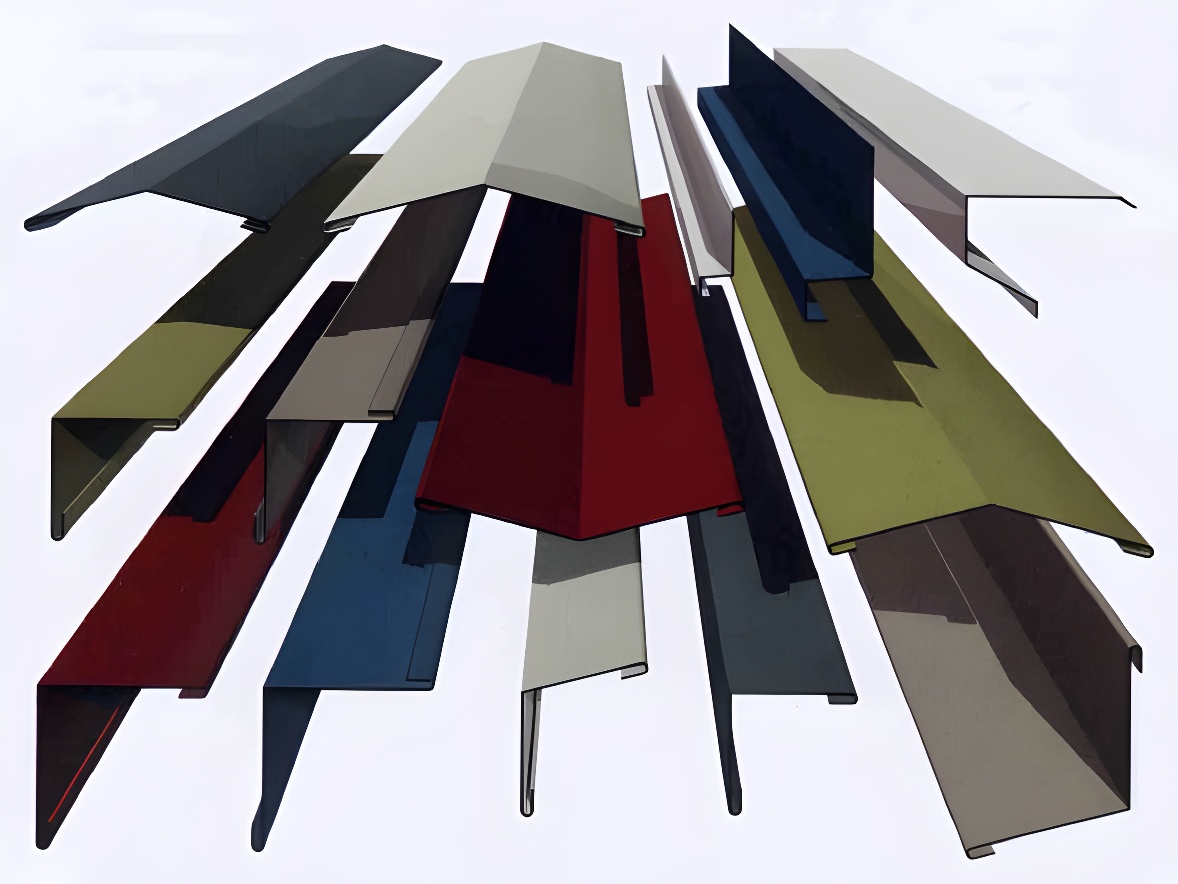

Flashings are produced as prefabricated sheets of various sizes in the factory and are installed at the specified location. Sandwich panels are a highly utilized product that has seen growing applications for roofing and wall coverings in various structures. The junction of these sandwich panels with one another and with other structural components features a slight gap, which, albeit minimal, may lead to aesthetic issues and allow the infiltration of moisture, heat, cold, and other elements. A measure known as flashing has been developed to address this issue. Given the variations in sandwich panels and their applications in various locations, there are also different types of flashings.

Sandwich panels are a form of prefabricated material produced in a factory and subsequently installed and utilized at the construction site. The prefabricated components are assembled in accordance with the drawings. It is essential that these components are securely fastened together in their entirety and without any joints. Even the tiniest joint or gap can render the insulating properties of the sandwich panel ineffective against moisture and heat. Flashings serve as a solution to cover these gaps and seal the structure effectively. They are utilized to seal or cover the edges of sandwich panels, the gaps between sandwich panels, the connections between the wall and the ceiling, as well as specific areas of the building such as window cornices, wall edges, and gable roofs, among others.

Advantages of flashings:

Roof flashing:

This product is commonly utilized to conceal the gable structure, seal the façade of a building, and prevent water from falling on the walls and façade. With a variety of thicknesses and for a variety of applications, this product is manufactured in both colored and uncolored sheets.

Borj Pooshesh Apadana Engineering Technical Group benefits from the expertise of experienced engineers employs the latest industrial machinery available globally, and sources the finest raw materials to produce and offer this product at the highest quality in a variety of sizes and colors.

Different types of flashings:

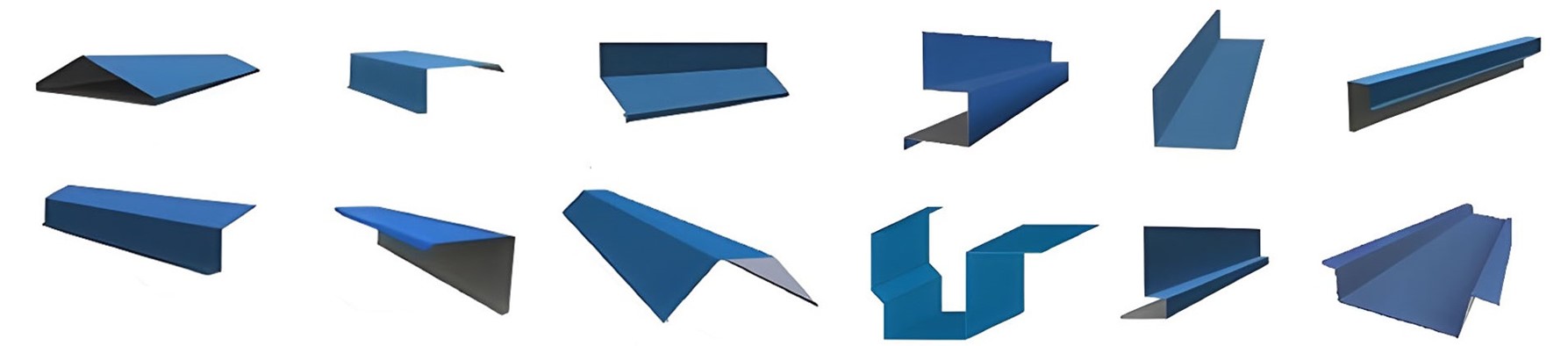

1.U model:

This model is produced in a U shape featuring a 90-degree angle.

Applications:

- Covering the complete perimeter of roof sandwich panels

- Covering the edges of wall sandwich panels

- As a holder for sandwich panels; it is affixed on its inner side by screws or rivets to the roof or floor of the structure, with the wall sandwich panel inserted within this sheet and secured by riveting

2- L-shaped corner model:

This model is crafted in an L shape featuring a 90-degree angle, with edges that are either bent inward or outward, ensuring the desired strength and beauty. The L-shaped corner model features wings measuring 10*10 cm or 5*5 cm, and it comes in a default white color. Certainly, it can be produced in any size and color you desire.

Applications:

- This model is available in two variations: colored on the inside or colored on the outside, designed for installation in corners where two walls converge. One is designated for the exterior, whereas the other suits the interior.

- This type of sheet can be utilized to cover the inside or outside horizontal connections between the roof and the wall.

- This model serves to conceal the seams between the ceiling and the wall, whether from the interior or exterior.

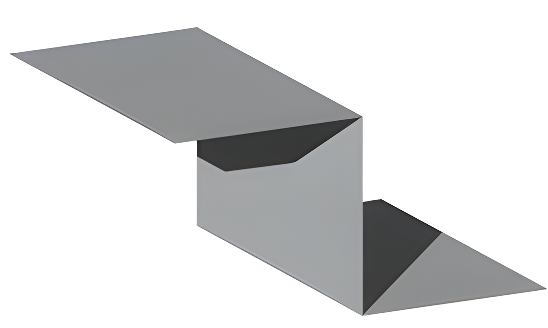

3- Three-foot Z-shaped model:

This model features a Z shape with a 90-degree angle, available in various sizes and colors, showcasing elegantly bent edges. This type of sheet primarily serves to provide protection against rotting or damage and to keep water from infiltrating the environment.

Applications:

- In the three-foot Z-shaped model, the front edge of the roof sandwich panel is installed at the gutter to complete the sealing. Its installation will protect the internal insulating layer of the sandwich panel from sunlight, chewing, birds, and more, while also improving the panel’s aesthetics.

- This type of sheet is utilized for both the bottom of wall sandwich panels and to cover the joint of the panels on walls, particularly shorter walls. In order to avoid decay and damage to the insulating layer and the sheet, as well as to direct as much water as possible to the outside of the shed or room, it is recommended to cover the edge of the wall sandwich panel that is placed on the ground or the sleeper wall during the installation of this model.

4 – Too crown ridge model:

The top crown ridge model stands apart from other models in significant ways. Flashings are usually produced using flat sheets, whereas the top crown ridge model is produced from stepped sheets that correspond to the pitch of the roof sandwich panel. This product successfully completes the sealing process. The top crown ridge model boasts numerous applications and a growing fan base. This model can also be produced in various colors, designs, and sizes. These sheets are curved at precise angles and possess a unique elegance.

Applications:

- This model is used to construct the top or the gable roof of sheds, especially at the breakpoint or the tip of the shed.

- Sealing the roof or connection between two roofs.

Price of flashings:

Borj Pooshesh Apadana Engineering Technical Group is dedicated to delivering high-quality products. Therefore, we offer different types of flashings with a wide range of lengths, thicknesses, and colors at competitive prices. Please contact our sales team to place an order or inquire about the pricing of flashings.

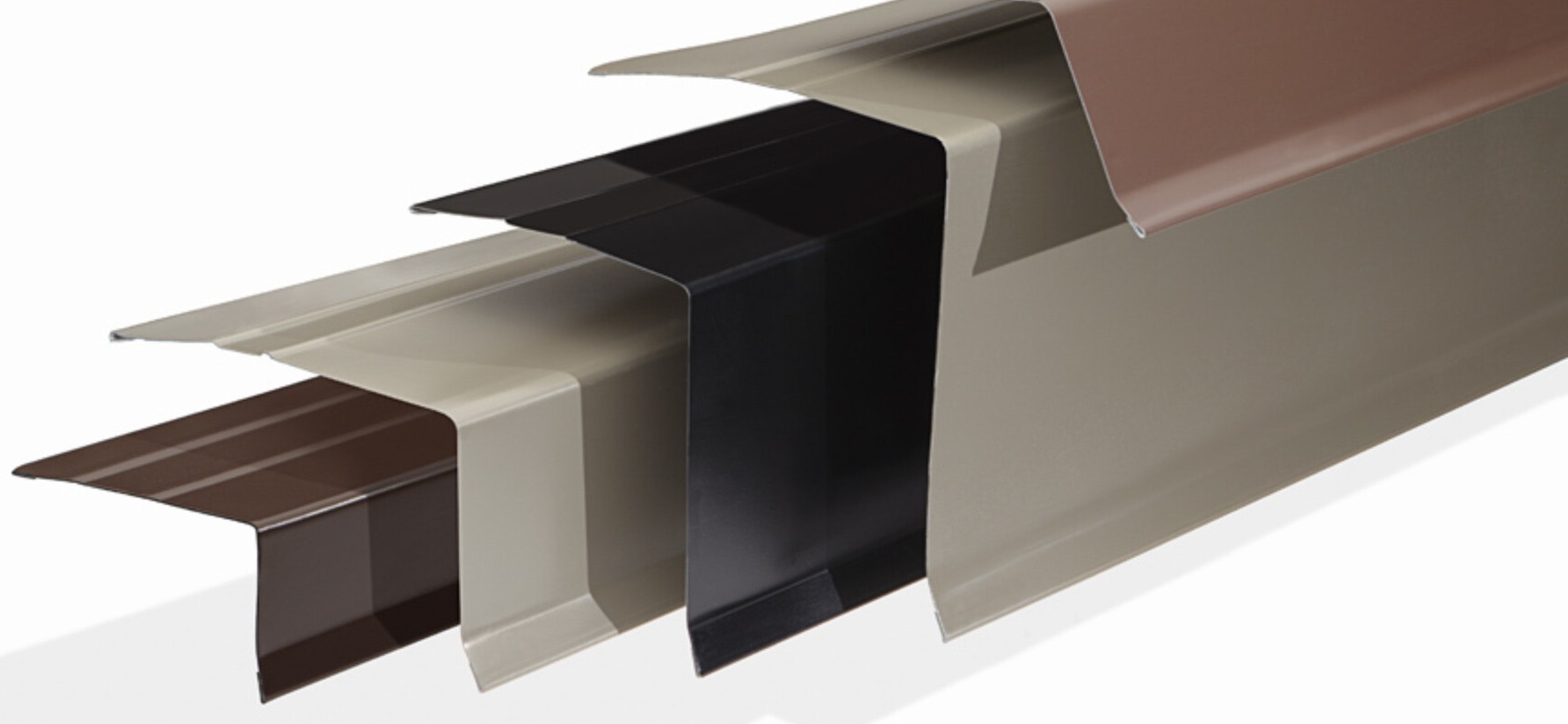

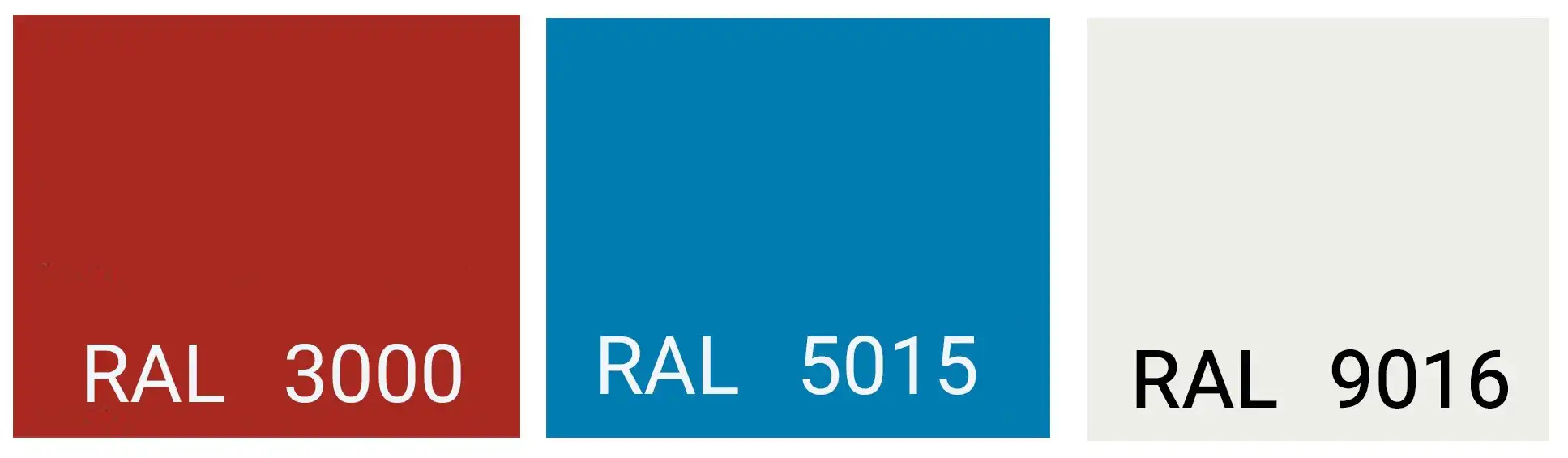

Colors of galvanized metal flashings:

Standard Colors

Special Colors