Roof Sandwich Panel:

Different types of roof sandwich panels offered by Borj Pooshesh Apadana Engineering Technical Group are as follows:

Roof Sandwich Panel:

Different types of roof sandwich panels offered by Borj Pooshesh Apadana Engineering Technical Group are as follows:

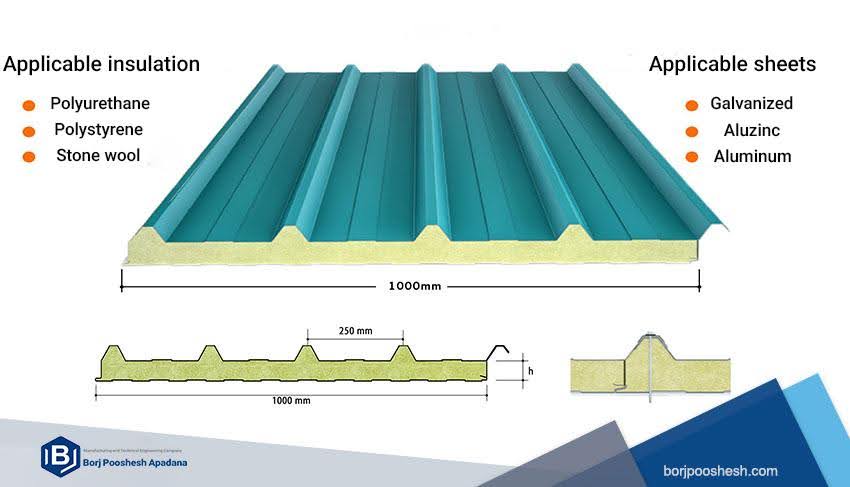

| Technical specifications | |

| Foam | PIR / PUR |

| Sheet material | Double-sided grooved/smooth sheet (galvanized/Aluzinc/aluminum) |

| Density | 40 kg/m3 |

| Thickness (cm) | 3-10 |

| Length (m) | 2-13/60 |

| Useful width (m) | 1 |

| Color scheme | Optional |

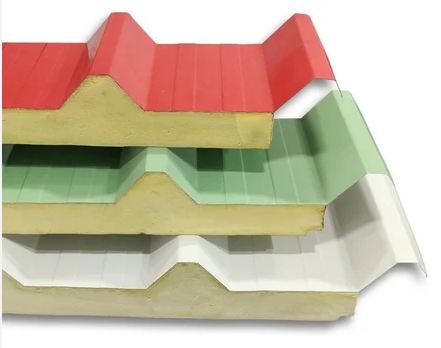

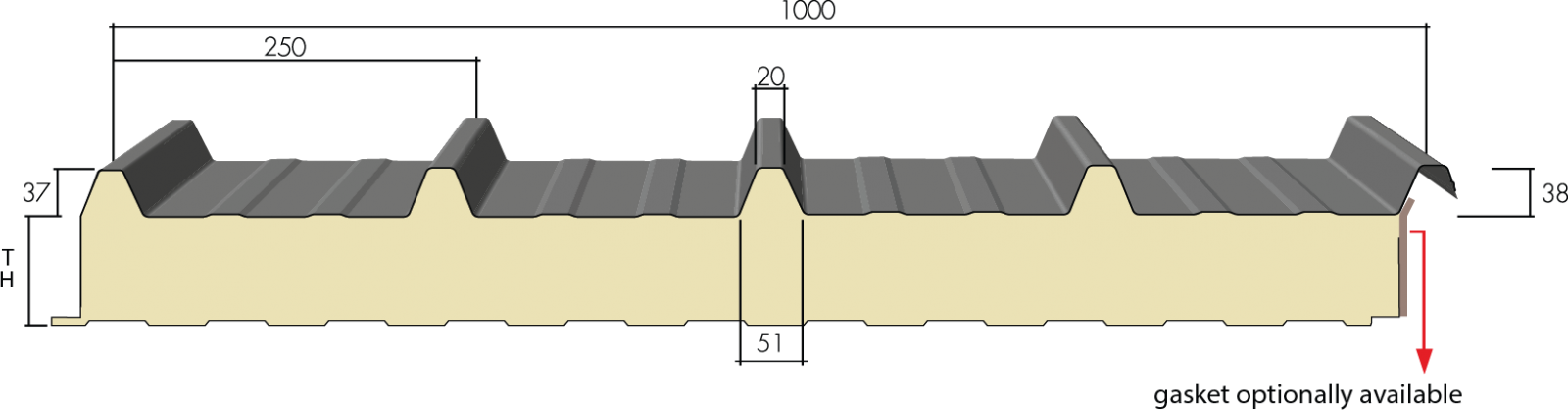

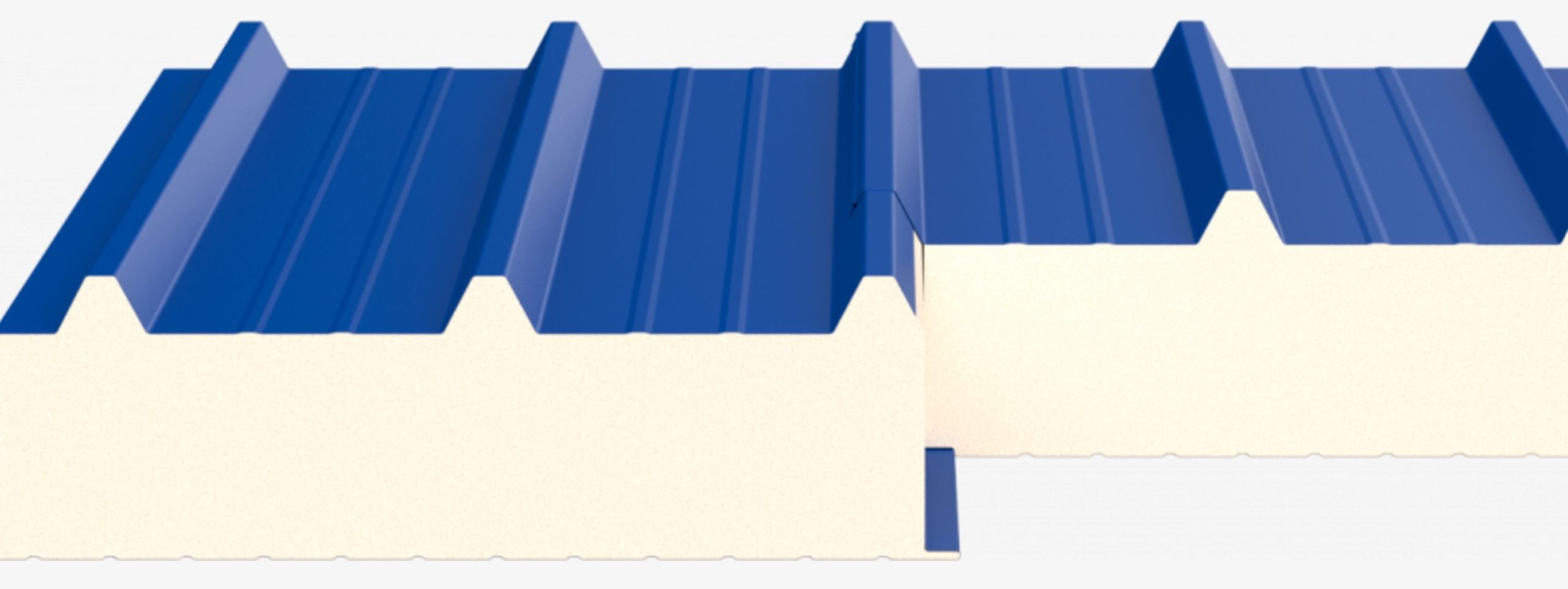

The roof sandwich panels provided by Apadana Borj Pooshesh Engineering Technical Group consist of three layers, featuring metal sheets on both sides and polyurethane (urethane) insulation and foam in between, ensuring resistance to heat and fire. Roof sandwich panel sheets are available in a variety of thicknesses and can be made in three different models: double-sided galvanized steel/Aluzinc/aluminum sheet, an internal single-sided galvanized steel/Aluzinc/aluminum sheet with an internal layer of aluminum foil, and a combination of galvanized and Aluzinc sheets. The trapezoidal design of the ribs in roof panels results in the overlapping of the two layers of sheets positioned above and below the panel, which prevents water leakage from the roof. The installation of roof panels entails laying the gutters and then covering them with the roofing materials. Finally, flashing sheets are used to finish the project. Roof sandwich panels are typically manufactured and installed with thicknesses ranging from 3 to 10 cm. This panel is utilized in the roofing of contemporary metal structures, including sheds, factories, halls, and roofed parking areas. Roof sandwich panels are designed and manufactured to ensure that they overlap effectively. Sandwich panels measure 1.07 cm in width, offering a useful width of 1 meter. These sandwich panels come in a variety of designs and colors, allowing you to select according to your preferences.

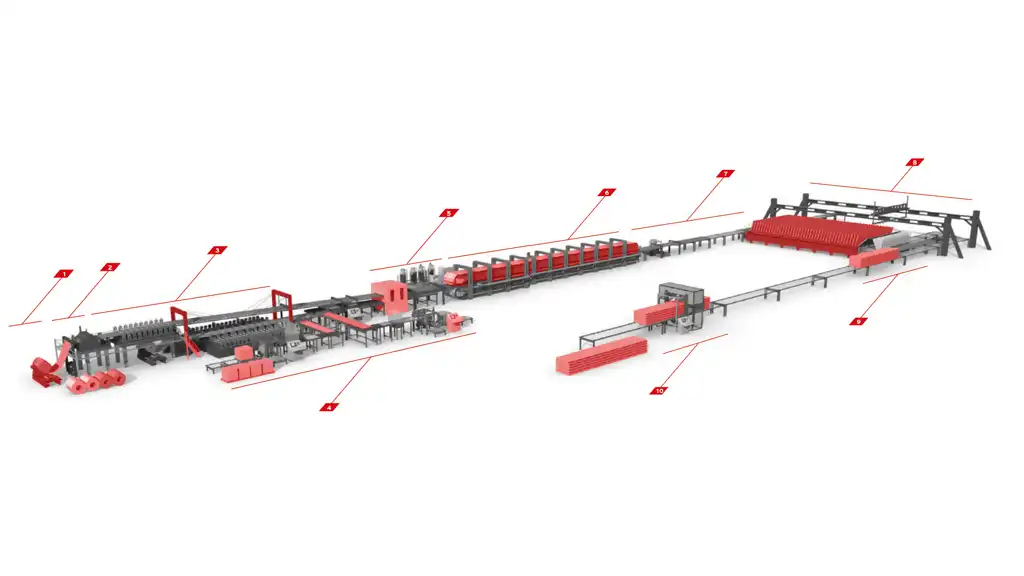

The procedure for manufacturing sandwich panels on the factory production line:

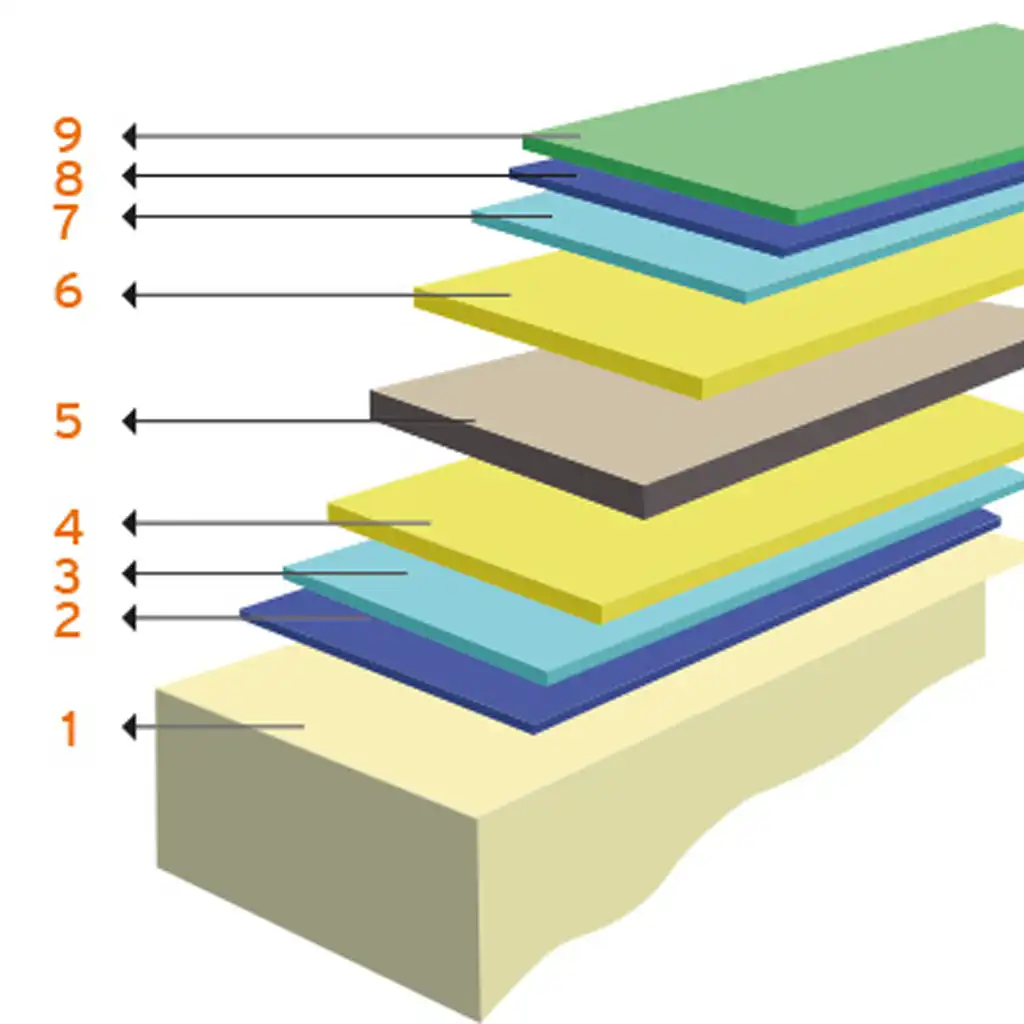

Components of Double-Sided Galvanized Roof Sandwich Panels:

✔ Polyurethane insulating foam:

The insulating foam is the most crucial component of double-sided galvanized roof sandwich panels. This product is manufactured using polyurethane insulating foam composed of isocyanate as the primary component and polyol serving as an additive. In the relevant device, these two materials are mixed under pressure and heat, causing their volume to increase rapidly by 20 to 30 times within a few seconds, resulting in a compact, cohesive, and integrated foam of the desired thickness. Polyurethane insulating foam is the most common type of foam globally, recognized for its exceptional resistance, outstanding adhesion, and tensile strength, as well as its effectiveness in insulating against corrosion, heat, cold, and sound, all while being lightweight.

✔ Galvanized Sheet:

Steel is a crucial construction and engineering material globally, due to its remarkable properties, including high ductility, durability, and impressive yield and tensile strength. The vulnerability of steel lies in its response to moisture. Various methods have been developed to protect steel from corrosion caused by moisture. One approach involves applying a layer of zinc metal. Steel coated with zinc metal is referred to as galvanized steel. The coating of steel with zinc is performed through electrochemical contact, utilizing a zinc anode and an iron cathode. Therefore, if the zinc coating is compromised, the iron remains safeguarded against corrosion and rusting of the underlying metal. Zinc-coated galvanized sheets featuring a zinc layer ranging within 100–275 g/m2 are manufactured through the hot-dip process on highly automated continuous lines known as coil coating. Once the coil is uncoiled, both the lower and upper surfaces undergo a cleaning process using specialized chemicals, followed by a pre-treatment that boosts corrosion resistance and improves paint adhesion. Then, a layer of primer is generously spread across both surfaces, setting the stage for a flawless finish. The back coating truly elevates the bond of the sandwich panel insulation core to new heights. Once the primer-coated surfaces are fully baked, the coating is applied to the front surface, ensuring a flawless finish. They are re-baked, allowed to cool down, and then carefully packed in pre-painted coils, ready to play their vital role in the production of sandwich panels.

Primer:

The double-sided galvanized roof sandwich panel consists of a central layer of polyurethane insulation foam, flanked by two layers of galvanized sheet on either side. The bonding of these three layers is achieved through the application of primer under pressure and heat. Primer is a material characterized by its exceptional durability, outstanding performance and efficiency, extended lifespan, and strong resistance, resulting in a robust connection. This material maintains its shape under both high and very low temperatures. It offers moisture resistance and is suitable for painting. Sandwich panels can be utilized in industrial settings where vibration is present. This material, similar to siliconized mastic, exhibits significant flexibility. Therefore, it excels in environments where the interconnected components are prone to vibration.

Installation of double-sided galvanized roof sandwich panels:

Installing these sandwich panels is straightforward and can be done quickly. For a seamless and effective project, it is advisable to entrust this task to our experienced professionals. This approach allows you to prevent any possible issues with the panels and ensure that the roof is sealed flawlessly. Our exceptional installation and implementation services are accessible across Iran, guaranteeing you receive them in record time! Additionally, Apadana Borj Pooshesh Engineering Technical Group is ready to provide you with outstanding services for the installation of sandwich panels

Price of double-sided galvanized roof sandwich panels:

Apadana Borj Pooshesh Engineering Technical Group is dedicated to delivering high-quality products. Therefore, we offer roof sandwich panels in a wide range of lengths, thicknesses, and colors at competitive prices. Please contact our sales team to place an order or inquire about the pricing of roof sandwich panels.

Installation of roof sandwich panels:

Apadana Borj Pooshesh Engineering Technical Group adheres to international standards for installing sandwich panels on the roofs of structures. The initial sign of installing sandwich panels is the combined and integrated application of polycarbonate along with sandwich panels. Accordingly, 18% of the roof covering must consist of polycarbonate, whereas the remaining 82% should be finished with sandwich panels. When sandwich panels are positioned side by side, they tend to overlap, creating a seamless connection that enhances the overall structure. When building a sturdy metal frame, the first step is to lay down those iron beams like a solid foundation. Next, the purlins are positioned horizontally atop them, creating a reliable support system. Finally, the roof sandwich panels are securely fastened to the purlins, ensuring everything is locked in place for a strong and durable structure. For example, in a project utilizing a 5-rib sandwich panel, the area beneath the fifth rib remains vacant, whereas the subsequent sandwich panel is positioned on the first rib, resulting in an overlap. Screws play a crucial role in keeping the ribs tightly secured together, ensuring everything stays in place just as expected. When it comes to drilling the ribs, a unique drill is employed to ensure everything goes smoothly and efficiently. The drill bit measures a solid 7 mm, whereas a slightly smaller 6 mm screw takes the spotlight. The reason behind this is that the volume of the perforated panel space experiences fluctuations due to the natural expansion and contraction processes. This handy little trick is also the secret sauce to really lock those panels together for a perfect fit! The fastening structure and the number of screws are designed to ensure that one screw is utilized at every rib along the gutter edges, particularly at the roof corners. However, in various areas, it is only the sections where the sandwich panels come together that are fastened with screws. Before installing the polycarbonates, which are sandwiched between the roof sandwich panels, it is necessary to finish assembling the panels. The work can proceed with the installation of the polycarbonates. Before the installation of polycarbonate on the purlins, it is essential to utilize central bracing brackets in the areas where the sandwich panel rib is devoid of support, ensuring that everything is perfectly aligned and secure throughout the process. In the parts where the ribs are fully intact, central bracing brackets are strategically positioned at an intermediate point on the purlins.

Double-sided aluminum roof sandwich panel:

This product is utilized in the roofing of different kinds of sheds, warehouses, cold storage facilities, and environments where hygiene is very important, such as clean rooms. Double-sided aluminum roof sandwich panels boast an impressively low weight of around 1 kg/m2. Despite their very low weight, they possess acceptable strength, though it is inferior to that of double-sided Aluzinc sandwich panels and double-sided galvanized roof sandwich panels. This article offers insights into this category of sandwich panels.

Specification of aluminum sheets:

Cold storage roof sandwich panels:

PUR/PIR cold storage roof sandwich panels are designed for warehouse structures where the internal temperature can drop to 0°C. The edges of the panels are custom-cut, resulting in a very low linear thermal conductivity coefficient at the joint while also guaranteeing complete sealing and vapor tightness.

Apadana Borj Pooshesh Engineering Technical Group presents cold storage roof sandwich panels with thicknesses of 8 and 10 cm in a variety of colors.

Apadana Borj Pooshesh Engineering Technical Group is dedicated to delivering high-quality products. Therefore, we offer cold storage roof sandwich panels with a range of lengths, thicknesses, and colors at competitive prices. Please contact our sales team to place an order or inquire about the pricing of roof sandwich panels.

Standard Colors

Special Colors